BMW invests in lithium startup Lilac Solutions

08 October 2021

An increasing number of car manufacturers are looking to startups to ramp up the development of new technologies. Porsche recently invested in an Israeli semiconductor specialist – a smart move, considering the ongoing chip crisis that has plagued the automotive industry. Another hotly debated topic is lithium, the key component in batteries found in electrically-chargeable vehicles (EVs).

BMW’s venture capital fund has now announced an investment in a lithium technology startup, Lilac Solutions, to support a more environmentally-friendly extraction of the mineral. The California-based company says it can extract lithium faster and cheaper – and this in itself is a unique selling point.

As the EV market continues to grow, carmakers are faced with high prices and lithium material shortages. A recent Benchmark report found prices of lithium carbonate reached a new all-time high due to limited supply and increasing demand, especially from China.

The automotive industry is also competing for batteries with other companies from the electric utilities and energy market, which is driving up demand even further. With traditional technologies for lithium production struggling to keep pace, startups such as Lilac are getting their chance to shine as they promise faster supply.

‘Innovative technologies provide better, more sustainable and more efficient access to raw materials. By investing in startups, we are speeding up development of new technologies, stimulating competition,’ said Wolfgang Obermaier, a senior vice president at BMW overseeing the segment of indirect goods and services, raw materials and production partners.

‘By investing in Lilac Solutions, we are supporting technological progress in the field of lithium extraction, with a focus on responsible and sustainable methods,’ he added.

Unlocking new lithium supplies

Much of the world’s lithium can be found in brine resources, which are natural deposits of salt water. While traditional mining for lithium is generally considered to be ‘dirty business’ and involves soil and air contamination, Lilac offers a more sustainable approach.

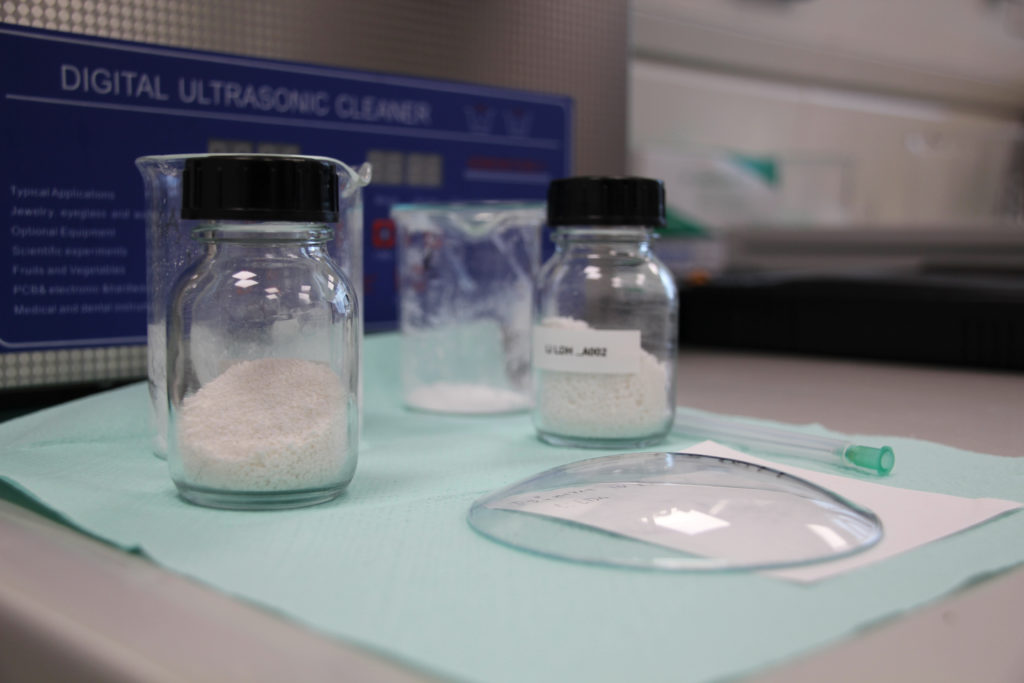

The tech startup has developed a new ion exchange technology that minimises the environmental impact. This allows for increased production of lithium while also returning brine back underground. In field pilots, Lilac demonstrated its novel technology, which could be used with brines worldwide – even when lithium content is low.

‘The lithium industry must innovate to meet the needs of battery and automotive companies, otherwise the transition to EVs will be delayed,’ said Dave Snydacker, CEO of Lilac Solutions. ‘We are delighted to add strategic partners who deeply understand each facet of lithium supply and support our mission of ramping production.’

It is not the first time BMW has looked to the sustainable supply chain of lithium. In 2019, the carmaker signed a contract with Ganfeng for sustainable lithium sourced from mines in Australia. Earlier this year, the manufacturer partnered with Livent for a second supply of the mineral. Other carmakers, including Volkswagen Group and Daimler, recently signed a partnership dedicated to the ‘responsible’ sourcing of lithium mining in Chile.

The clean-energy demands from carmakers have resulted in a lithium ‘gold rush’. A sustainable approach from startups such as Lilac or its peer Vulcan Energy Resources will be pivotal in helping manufacturers meet those needs.