Expanding ethics and boosting batteries with artificial intelligence

12 October 2020

12 October 2020

As increasingly intelligent vehicles roll off production lines, the need for smarter tooling is becoming more apparent. To ensure the successful digitalisation and electrification of cars, manufacturers are integrating artificial intelligence (AI) into their value chains.

Having already employed AI across its business, BMW Group (BMW) is now laying out rules for working with the technology. Meanwhile, InoBat Auto (InoBat) has announced the world’s first ′intelligent’ electric vehicle (EV) battery, developed with AI.

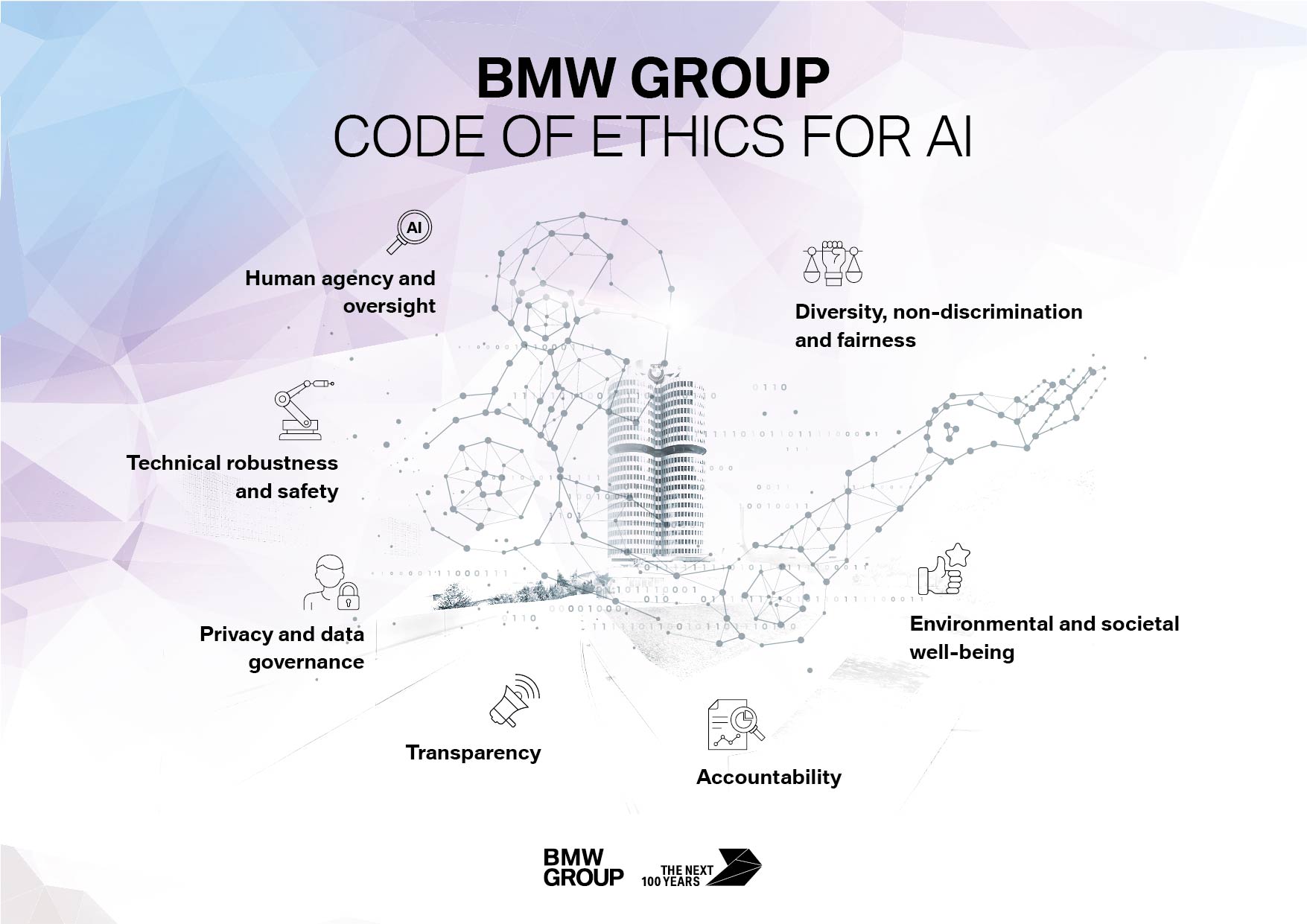

Seven principles

Building on requirements laid out by the EU for trustworthy AI, BMW has outlined seven principles which cover the use of the technology. They are:

Source: BMW Group

′Artificial intelligence is the key technology in the process of digital transformation. But for us, the focus remains on people,’ said Michael WÜrtenberger, head of project AI. ′Artificial intelligence supports our employees and improves the customer experience. We are proceeding purposefully and with caution in the expansion of AI applications within the company. The seven principles for AI at the BMW Group provide the basis for our approach.’

Project AI was launched in 2018 to ensure the new technology is used ethically and efficiency. At the core of the company’s competence for data analytics and machine learning, the project establishes rapid knowledge and technology sharing. AI is being used across the carmaker’s value chain from energy management in vehicles to robot control systems and driver assistance programmes.

InoBat’s ′intelligent’ EV battery

Speaking at the GLOBSEC Tatra Summit, InoBat CEO Marian Bocek, announced the launch of ′the world’s first intelligent battery.’ The EV component was developed through a combination of AI and high-throughput (HTP) technology.

By enhancing the production process with these advanced systems, the manufacturer claims it can make better batteries more quickly and efficiently than standard research methods. It also allows them to increase operational range for best-in-class EVs by almost 20%, while also reducing dependence on cobalt.

′No other battery-cell maker has the technology to discover and demonstrate battery chemistries as quick. InoBat can provide its customers with the ′best’ answer,’ said Bocek. ′The world’s first intelligent battery marks a huge leap forward in the electrification of transport. At InoBat, we want to fast track innovation to ensure the best batteries for any type of electric vehicle. These batteries will be tested and developed further with scale production starting next year.’

The company is developing an AI-driven battery research centre and production line in Voderady, Slovakia, where ′intelligent battery’ production will begin in 2021. InoBat is also advancing plans to build a €1 billion, 10-GWh gigafactory with the potential to provide 240,000 EVs with bespoke batteries in 2025.

Source: BMW Group

′Artificial intelligence is the key technology in the process of digital transformation. But for us, the focus remains on people,’ said Michael WÜrtenberger, head of project AI. ′Artificial intelligence supports our employees and improves the customer experience. We are proceeding purposefully and with caution in the expansion of AI applications within the company. The seven principles for AI at the BMW Group provide the basis for our approach.’

Project AI was launched in 2018 to ensure the new technology is used ethically and efficiency. At the core of the company’s competence for data analytics and machine learning, the project establishes rapid knowledge and technology sharing. AI is being used across the carmaker’s value chain from energy management in vehicles to robot control systems and driver assistance programmes.

InoBat’s ′intelligent’ EV battery

Speaking at the GLOBSEC Tatra Summit, InoBat CEO Marian Bocek, announced the launch of ′the world’s first intelligent battery.’ The EV component was developed through a combination of AI and high-throughput (HTP) technology.

By enhancing the production process with these advanced systems, the manufacturer claims it can make better batteries more quickly and efficiently than standard research methods. It also allows them to increase operational range for best-in-class EVs by almost 20%, while also reducing dependence on cobalt.

′No other battery-cell maker has the technology to discover and demonstrate battery chemistries as quick. InoBat can provide its customers with the ′best’ answer,’ said Bocek. ′The world’s first intelligent battery marks a huge leap forward in the electrification of transport. At InoBat, we want to fast track innovation to ensure the best batteries for any type of electric vehicle. These batteries will be tested and developed further with scale production starting next year.’

The company is developing an AI-driven battery research centre and production line in Voderady, Slovakia, where ′intelligent battery’ production will begin in 2021. InoBat is also advancing plans to build a €1 billion, 10-GWh gigafactory with the potential to provide 240,000 EVs with bespoke batteries in 2025.

- Human agency and oversight;

- Technical robustness and safety;

- Privacy and data governance

- Transparency;

- Diversity, non-discrimination and fairness;

- Environmental and social wellbeing; and

- Accountability.

Source: BMW Group

′Artificial intelligence is the key technology in the process of digital transformation. But for us, the focus remains on people,’ said Michael WÜrtenberger, head of project AI. ′Artificial intelligence supports our employees and improves the customer experience. We are proceeding purposefully and with caution in the expansion of AI applications within the company. The seven principles for AI at the BMW Group provide the basis for our approach.’

Project AI was launched in 2018 to ensure the new technology is used ethically and efficiency. At the core of the company’s competence for data analytics and machine learning, the project establishes rapid knowledge and technology sharing. AI is being used across the carmaker’s value chain from energy management in vehicles to robot control systems and driver assistance programmes.

InoBat’s ′intelligent’ EV battery

Speaking at the GLOBSEC Tatra Summit, InoBat CEO Marian Bocek, announced the launch of ′the world’s first intelligent battery.’ The EV component was developed through a combination of AI and high-throughput (HTP) technology.

By enhancing the production process with these advanced systems, the manufacturer claims it can make better batteries more quickly and efficiently than standard research methods. It also allows them to increase operational range for best-in-class EVs by almost 20%, while also reducing dependence on cobalt.

′No other battery-cell maker has the technology to discover and demonstrate battery chemistries as quick. InoBat can provide its customers with the ′best’ answer,’ said Bocek. ′The world’s first intelligent battery marks a huge leap forward in the electrification of transport. At InoBat, we want to fast track innovation to ensure the best batteries for any type of electric vehicle. These batteries will be tested and developed further with scale production starting next year.’

The company is developing an AI-driven battery research centre and production line in Voderady, Slovakia, where ′intelligent battery’ production will begin in 2021. InoBat is also advancing plans to build a €1 billion, 10-GWh gigafactory with the potential to provide 240,000 EVs with bespoke batteries in 2025.

Source: BMW Group

′Artificial intelligence is the key technology in the process of digital transformation. But for us, the focus remains on people,’ said Michael WÜrtenberger, head of project AI. ′Artificial intelligence supports our employees and improves the customer experience. We are proceeding purposefully and with caution in the expansion of AI applications within the company. The seven principles for AI at the BMW Group provide the basis for our approach.’

Project AI was launched in 2018 to ensure the new technology is used ethically and efficiency. At the core of the company’s competence for data analytics and machine learning, the project establishes rapid knowledge and technology sharing. AI is being used across the carmaker’s value chain from energy management in vehicles to robot control systems and driver assistance programmes.

InoBat’s ′intelligent’ EV battery

Speaking at the GLOBSEC Tatra Summit, InoBat CEO Marian Bocek, announced the launch of ′the world’s first intelligent battery.’ The EV component was developed through a combination of AI and high-throughput (HTP) technology.

By enhancing the production process with these advanced systems, the manufacturer claims it can make better batteries more quickly and efficiently than standard research methods. It also allows them to increase operational range for best-in-class EVs by almost 20%, while also reducing dependence on cobalt.

′No other battery-cell maker has the technology to discover and demonstrate battery chemistries as quick. InoBat can provide its customers with the ′best’ answer,’ said Bocek. ′The world’s first intelligent battery marks a huge leap forward in the electrification of transport. At InoBat, we want to fast track innovation to ensure the best batteries for any type of electric vehicle. These batteries will be tested and developed further with scale production starting next year.’

The company is developing an AI-driven battery research centre and production line in Voderady, Slovakia, where ′intelligent battery’ production will begin in 2021. InoBat is also advancing plans to build a €1 billion, 10-GWh gigafactory with the potential to provide 240,000 EVs with bespoke batteries in 2025.