How new technology can boost electric-vehicle efficiency

10 February 2023

Carmakers are investing huge sums into electrification, launching new models, building factories, and developing technologies to increase electric-vehicle (EV) performance. While improving battery technology is often seen as essential to boost EV range and efficiency, there are other – and maybe – surprising ways to achieve this.

Market-ready heat belt

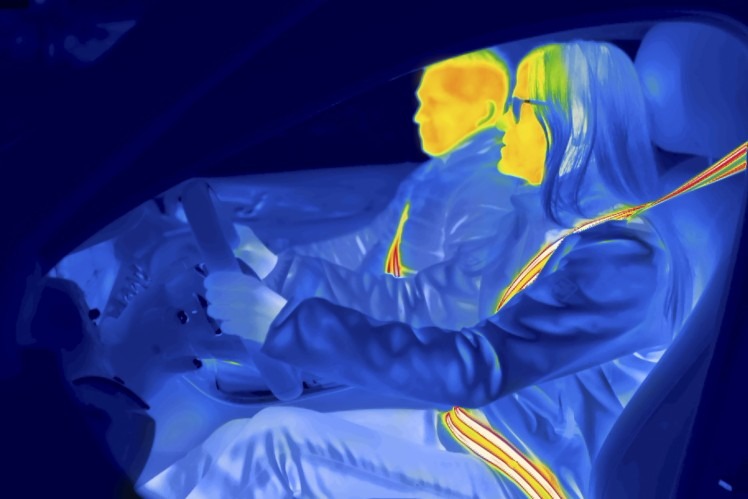

German automotive supplier ZF is one of the technology companies eager to boost EV energy efficiency. The supplier has created a heated seat belt to help drivers save on energy used to warm up the car. How does it work? The seat belt has heating conductors woven into the textile structure – similar to an electric blanket.

The so-called ‘heat belt’ may sound like an extravagant accessory, but ZF has thought things through. It claims the system is of particular use when temperatures drop as it can increase range by up to 15% by lowering the energy needed to heat up the cabin.

In EVs, heating the cabin consumes a lot of energy and has a direct impact on range as climate-control systems are powered by the battery. Additionally, battery-electric vehicles (BEVs) do not have access to the same excess of usable waste heat that internal-combustion engine (ICE) models do.

Cold temperatures can also lower the range of BEVs by up to 30%. This is mainly because the batteries work best between 20 and 40 degrees Celsius. ZF said that its pragmatic seat belt can generate temperatures ranging between 36 and 40 degrees Celsius to keep passengers warm.

The novel feature operates like a conventional seat belt, with the company hoping for broad consumer acceptance as it can be used in series production. ZF is working with major automotive groups, which are already showing interest in the technology. Indeed, a few years from now the ‘heat belt’ could become mainstream.

‘The ZF heat belt is market-ready and we are in the bidding phase for first serial contracts, i.e. discussions [and] trials with OEMs are running. Therefore, we expect the first cars on the road within the next two to three years,’ a ZF spokesperson told Autovista24.

Sound and EV efficiency

ZF’s ‘heat belt’ perfectly demonstrates how a product that is not directly related to the powertrain can add to EV efficiency and range. But it is in no way the only example. Panasonic Automotive is also targeting BEVs and unveiled a new audio system at last month’s CES 2023.

The supplier promises customers a high-quality listening experience with reduced energy consumption and weight – key metrics that can improve EV range. Panasonic called the patent-pending system more environmentally friendly and efficient.

The company highlighted that its audio technology can boost vehicle efficiency by cutting the system’s power draw. In tests, Panasonic found that its audio system can lower power consumption by up to 67%. This in turn helps conserve energy that can be redirected to increase range.

While Panasonic was unable to disclose to Autovista24 when the EV audio technology would be available to the broader market, a spokesperson confirmed that the company had received ‘phenomenal’ interest from customers. ‘We are excited that our enhanced EV audio system is ushering in a new wave of vehicle-component design based on improved efficiency,’ the spokesperson added.

Panasonic is aiming for minimalist packaging and size, which it said helps manufacturers reduce production costs. The audio system also needs less gauge wiring, which comes with several benefits. It weighs less, takes up less space, and requires smaller amounts of metals, such as copper.

There are no door-mounted speakers, which can instead be found in more central locations to move the sound directly to the driver and passengers. Panasonic has clearly targeted EVs with its innovative audio system, with the aim of improving specific BEV applications by focusing on space, weight, power, and costs.

Software advances

Software providers are also part of the search for greater EV efficiency. Qnovo, a battery-intelligence software company, has developed a management system that relies on predictive analytics and can bolster efficiency.

Qnovo co-founder and CEO, Nadim Maluf, told Autovista24 that ‘by augmenting battery chemistry with intelligent algorithms and machine learning, our solution improves battery performance, EV range by up to 10%, and safety in all types of electric vehicles with any type of lithium-ion battery.’

The company has created technology that slows down battery degradation through optimised charging. ‘Continual optimisation of batteries, from fast charging to the management of degradation, provides a longer lifespan for the entire energy-storage system,’ Maluf added.

Qnovo supplies its software to leading automotive manufacturers and interest in its technology has grown from carmakers worldwide, including in Europe, Maluf said.

Tyres and torque

Other automotive suppliers are also focussing on EV-specific solutions, including Germany-based technology company Continental.

‘When it comes to electrification, Continental is in the fast lane,’ a spokesperson told Autovista24. ‘This applies to novel drive systems and beyond, with its product spectrum extending from innovative tyres to high-performance computers and interactive displays for the connected cockpit to intelligent brake systems.’

Tyres are a focal point for Continental when it comes to EV efficiency as they have a clear impact on performance. BEVs are heavier than ICE-powered vehicles because of their weighty batteries. This puts an additional strain on the tyres, also leading to longer braking distances.

But there is another reason why EVs benefit from specially-designed tyres: electric engine torque. BEVs generate a lot more torque than diesel and petrol cars, which means faster acceleration. This instant torque can increase wear and tear. In short, tyre requirements for EVs differ.

Low-rolling resistance tyres help to drive down energy consumption and increase range. Continental’s ContiSeal technology can also repair 80% of all tyre punctures, helping remove the need for a spare wheel, and cutting down on weight. Carmakers are relying on the company’s EV tyres, including Tesla, Polestar, Mercedes-Benz, BYD, Kia, and Porsche.

Motor power

But one can hardly talk about EV efficiency without mentioning motors. Texas-based Infinitum recently unveiled its next-generation, axial flux propulsion and traction electric motor that can maximise EV range for passenger and commercial vehicles.

Known as Aircore Mobility, the motor delivers high power and torque density. It has many use cases including aviation, marine, construction, agricultural, and auxiliary applications.

The company told Autovista24 that Aircore Mobility will be available in the second quarter of 2023, with carmakers showing keen interest.

‘Infinitum is in discussions with multiple tier 1 passenger vehicle and commercial trucking OEMs,’ a spokesperson said, adding that Infinitum is also talking to an electric racing team and electric power supplier.

The motor replaces the heavy copper-wound iron stators usually found in a motor, with a lightweight counterpart – a printed circuit board (PCB) stator. Infinitum said its motor is more reliable than a conventional one. It is also 10% more efficient, 50% smaller and lighter, and requires 66% less copper.

The main advantage of the PCB stator is that it boosts efficiency while reducing mechanical losses, as well as noise and vibration. The company also said that the motor can achieve up to five times the current density of a conventional, liquid-cooled motor.

‘Infinitum is pioneering a new approach in liquid cooling to enhance the power density of its motors,’ the spokesperson said. It uses a liquid cooling method that allows the coolant to be in direct contact with the stator. This then mitigates heat across a larger surface area and extends life.

The search for EV efficiency is multifaceted and new technology can help improve range and extend the life of a vehicle. Since carmakers are spending billions on electrification, improving EV performance is key, no matter how small or large the gains are.