Mercedes-Benz to source battery materials from certified mines

17 November 2020

17 November 2020

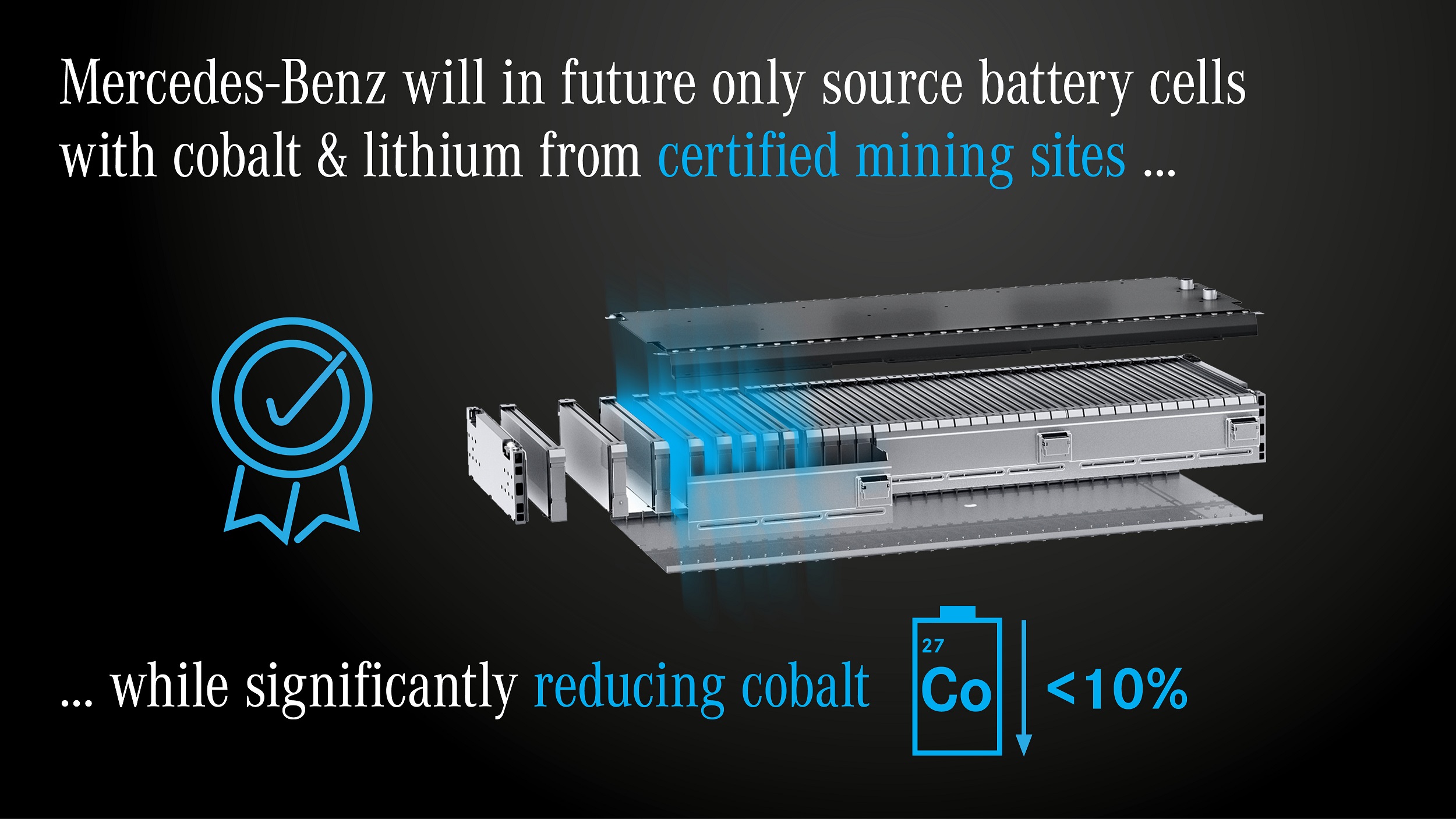

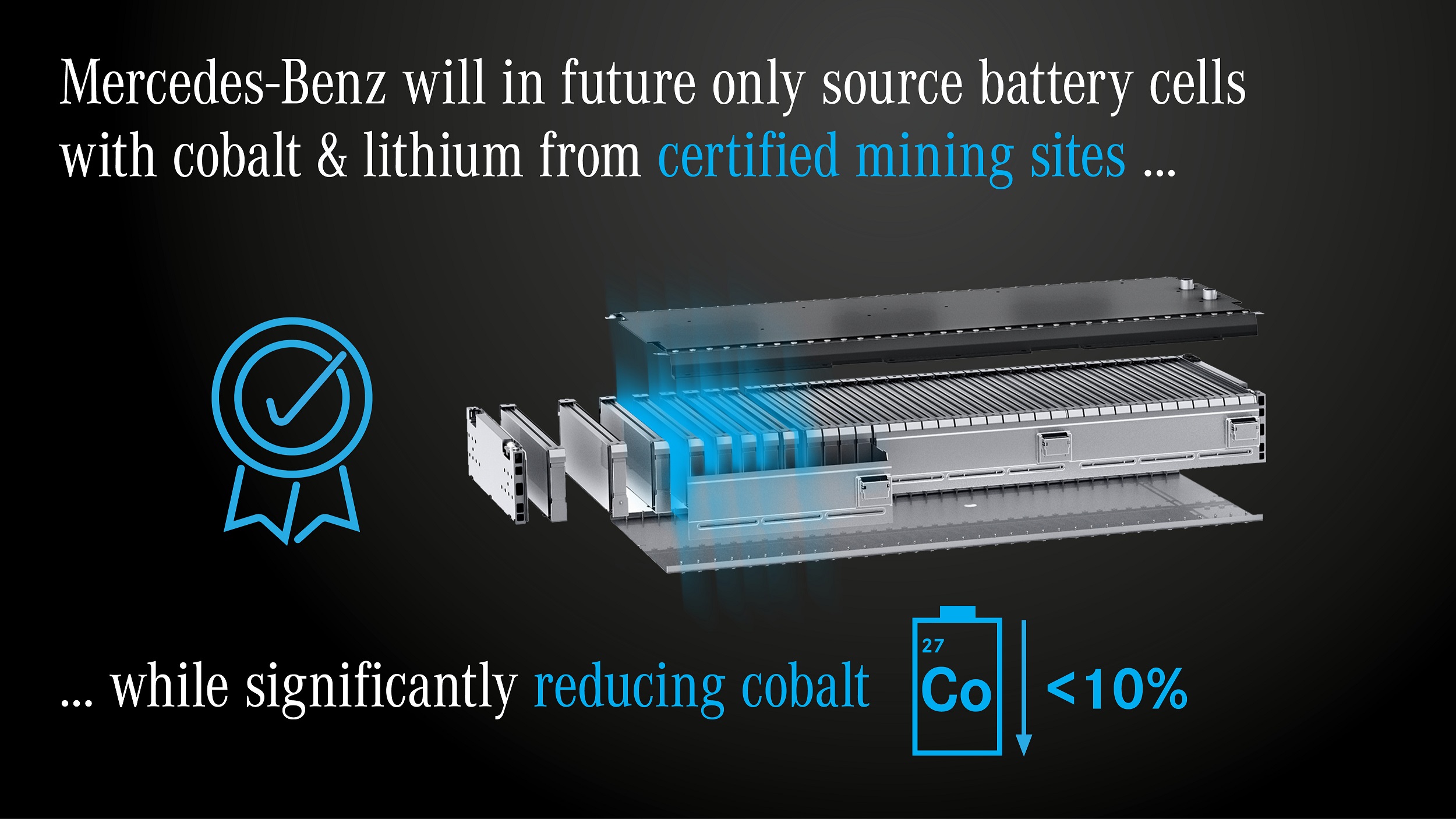

Daimler-owned luxury carmaker, Mercedes-Benz, will use cobalt and lithium exclusively from certified mines. This switch to sustainable supply chains will ensure its electric fleet will be powered by ethically-sourced materials, with the aim of protecting human rights and the environment.

Mercedes-Benz is already reducing the cobalt content in its upcoming generations of battery cells to less than 10%. Looking ahead to its future electrically-chargeable vehicles (EVs), the manufacturer intends to dispense with materials like cobalt entirely through post-lithium-ion capabilities and new material compositions.

Sustainability is central to the Mercedes-Benz purchasing strategy. On its way to CO2-neutrality within the ′Ambition 2039′ framework, the focus is CO2 emission reduction, as well as safeguarding human rights and the responsible use of resources along the supply chain.

Source: Mercedes-Benz

Standards and initiatives

The carmaker wants to become a pioneer of socially-acceptable and environmentally friendly cobalt and lithium extraction, two fundamental resources in the manufacturing of EV batteries. The company is relying on the industry recognised standard for responsible mining of the Initiative for Responsible Mining Assurance (IRMA) a key factor for making supplier decisions and forming contracts within its raw material supply chains.

The standard is still in the early stage of industry adoption, but this is something the carmaker is hoping to accelerate. In its contracts, Mercedes-Benz’ partners will also need to commit to sourcing from suppliers who are audited under the IRMA mining standard. In future, supply chains will also be regularly monitored. ′We have had the supply chains for our Mercedes-Benz electric-vehicle fleet audited in line with OECD guidance, all the way back to the mine, even though we don’t source cobalt directly ourselves,’ said Markus Schäfer, member of the board of management for Daimler and Mercedes-Benz; responsible for Daimler group research and Mercedes-Benz Cars COO.

′Based on the insights gained, we will instruct our battery suppliers to only source cobalt and lithium from certified mining sites in the future. With this, we even go a step further and will ensure our sourcing is from mining sites compliant with the mining standard of the ‘Initiative for Responsible Mining Assurance.’ He went on to explain that, ′this way, in addition to child labour and a range of other social concerns, environmental risks in the mining of raw materials can also be minimised. By doing so, we are paving the way for clean raw materials, from which other participants in the market can also benefit.’

Sustainable sourcing

Countries of origin considered ′high-risk’ are not generally excluded as sources of supply, in accordance with using leverage before withdrawal. Instead, the aim is to improve the situation for local people, strengthening their working rights. This follows the recommendations of non-governmental organisations, governments and other relevant interest groups, not to withdraw from high-risk countries.

In 2018, Mercedes-Benz commissioned the auditing of cobalt supply chains as per due diligence of the Organisation for Economic Co-operation and Development (OECD). More than 120 suppliers were identified, and 60 audits were conducted. Currently, there are no cobalt mines certified under IRMA’s standard for responsible mining.

Mercedes-Benz is working on a step-by-step approach for dealing with particularly challenging local situations, which will be taken with a limited number of cobalt mines in the Democratic Republic of the Congo. This will involve auditing them against a series of specific sets of requirements in the IRMA standard for responsible mining. In addition to human rights, the environmentally friendly mining of raw materials and other key aspects relating to industrial mining are examined.

In the medium term, this approach aims to formulate realistic expectations of the mining suppliers, while pressing for increasingly responsible practices. The long-term objective is a clear commitment to a process of continuous improvement. Included in this are transitional periods for the achievement of different levels of performance for an IRMA certification.

Source: Mercedes-Benz

Standards and initiatives

The carmaker wants to become a pioneer of socially-acceptable and environmentally friendly cobalt and lithium extraction, two fundamental resources in the manufacturing of EV batteries. The company is relying on the industry recognised standard for responsible mining of the Initiative for Responsible Mining Assurance (IRMA) a key factor for making supplier decisions and forming contracts within its raw material supply chains.

The standard is still in the early stage of industry adoption, but this is something the carmaker is hoping to accelerate. In its contracts, Mercedes-Benz’ partners will also need to commit to sourcing from suppliers who are audited under the IRMA mining standard. In future, supply chains will also be regularly monitored. ′We have had the supply chains for our Mercedes-Benz electric-vehicle fleet audited in line with OECD guidance, all the way back to the mine, even though we don’t source cobalt directly ourselves,’ said Markus Schäfer, member of the board of management for Daimler and Mercedes-Benz; responsible for Daimler group research and Mercedes-Benz Cars COO.

′Based on the insights gained, we will instruct our battery suppliers to only source cobalt and lithium from certified mining sites in the future. With this, we even go a step further and will ensure our sourcing is from mining sites compliant with the mining standard of the ‘Initiative for Responsible Mining Assurance.’ He went on to explain that, ′this way, in addition to child labour and a range of other social concerns, environmental risks in the mining of raw materials can also be minimised. By doing so, we are paving the way for clean raw materials, from which other participants in the market can also benefit.’

Sustainable sourcing

Countries of origin considered ′high-risk’ are not generally excluded as sources of supply, in accordance with using leverage before withdrawal. Instead, the aim is to improve the situation for local people, strengthening their working rights. This follows the recommendations of non-governmental organisations, governments and other relevant interest groups, not to withdraw from high-risk countries.

In 2018, Mercedes-Benz commissioned the auditing of cobalt supply chains as per due diligence of the Organisation for Economic Co-operation and Development (OECD). More than 120 suppliers were identified, and 60 audits were conducted. Currently, there are no cobalt mines certified under IRMA’s standard for responsible mining.

Mercedes-Benz is working on a step-by-step approach for dealing with particularly challenging local situations, which will be taken with a limited number of cobalt mines in the Democratic Republic of the Congo. This will involve auditing them against a series of specific sets of requirements in the IRMA standard for responsible mining. In addition to human rights, the environmentally friendly mining of raw materials and other key aspects relating to industrial mining are examined.

In the medium term, this approach aims to formulate realistic expectations of the mining suppliers, while pressing for increasingly responsible practices. The long-term objective is a clear commitment to a process of continuous improvement. Included in this are transitional periods for the achievement of different levels of performance for an IRMA certification.

Source: Mercedes-Benz

Standards and initiatives

The carmaker wants to become a pioneer of socially-acceptable and environmentally friendly cobalt and lithium extraction, two fundamental resources in the manufacturing of EV batteries. The company is relying on the industry recognised standard for responsible mining of the Initiative for Responsible Mining Assurance (IRMA) a key factor for making supplier decisions and forming contracts within its raw material supply chains.

The standard is still in the early stage of industry adoption, but this is something the carmaker is hoping to accelerate. In its contracts, Mercedes-Benz’ partners will also need to commit to sourcing from suppliers who are audited under the IRMA mining standard. In future, supply chains will also be regularly monitored. ′We have had the supply chains for our Mercedes-Benz electric-vehicle fleet audited in line with OECD guidance, all the way back to the mine, even though we don’t source cobalt directly ourselves,’ said Markus Schäfer, member of the board of management for Daimler and Mercedes-Benz; responsible for Daimler group research and Mercedes-Benz Cars COO.

′Based on the insights gained, we will instruct our battery suppliers to only source cobalt and lithium from certified mining sites in the future. With this, we even go a step further and will ensure our sourcing is from mining sites compliant with the mining standard of the ‘Initiative for Responsible Mining Assurance.’ He went on to explain that, ′this way, in addition to child labour and a range of other social concerns, environmental risks in the mining of raw materials can also be minimised. By doing so, we are paving the way for clean raw materials, from which other participants in the market can also benefit.’

Sustainable sourcing

Countries of origin considered ′high-risk’ are not generally excluded as sources of supply, in accordance with using leverage before withdrawal. Instead, the aim is to improve the situation for local people, strengthening their working rights. This follows the recommendations of non-governmental organisations, governments and other relevant interest groups, not to withdraw from high-risk countries.

In 2018, Mercedes-Benz commissioned the auditing of cobalt supply chains as per due diligence of the Organisation for Economic Co-operation and Development (OECD). More than 120 suppliers were identified, and 60 audits were conducted. Currently, there are no cobalt mines certified under IRMA’s standard for responsible mining.

Mercedes-Benz is working on a step-by-step approach for dealing with particularly challenging local situations, which will be taken with a limited number of cobalt mines in the Democratic Republic of the Congo. This will involve auditing them against a series of specific sets of requirements in the IRMA standard for responsible mining. In addition to human rights, the environmentally friendly mining of raw materials and other key aspects relating to industrial mining are examined.

In the medium term, this approach aims to formulate realistic expectations of the mining suppliers, while pressing for increasingly responsible practices. The long-term objective is a clear commitment to a process of continuous improvement. Included in this are transitional periods for the achievement of different levels of performance for an IRMA certification.

Source: Mercedes-Benz

Standards and initiatives

The carmaker wants to become a pioneer of socially-acceptable and environmentally friendly cobalt and lithium extraction, two fundamental resources in the manufacturing of EV batteries. The company is relying on the industry recognised standard for responsible mining of the Initiative for Responsible Mining Assurance (IRMA) a key factor for making supplier decisions and forming contracts within its raw material supply chains.

The standard is still in the early stage of industry adoption, but this is something the carmaker is hoping to accelerate. In its contracts, Mercedes-Benz’ partners will also need to commit to sourcing from suppliers who are audited under the IRMA mining standard. In future, supply chains will also be regularly monitored. ′We have had the supply chains for our Mercedes-Benz electric-vehicle fleet audited in line with OECD guidance, all the way back to the mine, even though we don’t source cobalt directly ourselves,’ said Markus Schäfer, member of the board of management for Daimler and Mercedes-Benz; responsible for Daimler group research and Mercedes-Benz Cars COO.

′Based on the insights gained, we will instruct our battery suppliers to only source cobalt and lithium from certified mining sites in the future. With this, we even go a step further and will ensure our sourcing is from mining sites compliant with the mining standard of the ‘Initiative for Responsible Mining Assurance.’ He went on to explain that, ′this way, in addition to child labour and a range of other social concerns, environmental risks in the mining of raw materials can also be minimised. By doing so, we are paving the way for clean raw materials, from which other participants in the market can also benefit.’

Sustainable sourcing

Countries of origin considered ′high-risk’ are not generally excluded as sources of supply, in accordance with using leverage before withdrawal. Instead, the aim is to improve the situation for local people, strengthening their working rights. This follows the recommendations of non-governmental organisations, governments and other relevant interest groups, not to withdraw from high-risk countries.

In 2018, Mercedes-Benz commissioned the auditing of cobalt supply chains as per due diligence of the Organisation for Economic Co-operation and Development (OECD). More than 120 suppliers were identified, and 60 audits were conducted. Currently, there are no cobalt mines certified under IRMA’s standard for responsible mining.

Mercedes-Benz is working on a step-by-step approach for dealing with particularly challenging local situations, which will be taken with a limited number of cobalt mines in the Democratic Republic of the Congo. This will involve auditing them against a series of specific sets of requirements in the IRMA standard for responsible mining. In addition to human rights, the environmentally friendly mining of raw materials and other key aspects relating to industrial mining are examined.

In the medium term, this approach aims to formulate realistic expectations of the mining suppliers, while pressing for increasingly responsible practices. The long-term objective is a clear commitment to a process of continuous improvement. Included in this are transitional periods for the achievement of different levels of performance for an IRMA certification.