Toyota to make its virtual crash test dummy freely available

16 June 2020

16 June 2020

Toyota is making its virtual human-modelling software free to access as of 2021. The Total Human Model for Safety (THUMS) system allows for the computer simulation and analysis of injuries sustained in different types of vehicle collision. In effect, the digitalisation of the crash test dummy.

In making THUMS available for mass use, Toyota is hoping to help build a safer mobility society. The Japanese manufacturer wants to influence the safer design of cars, systems and equipment in the automotive industry. The software’s usability will also benefit as further improvements are made and shared across the user base.

Virtual crash test dummy

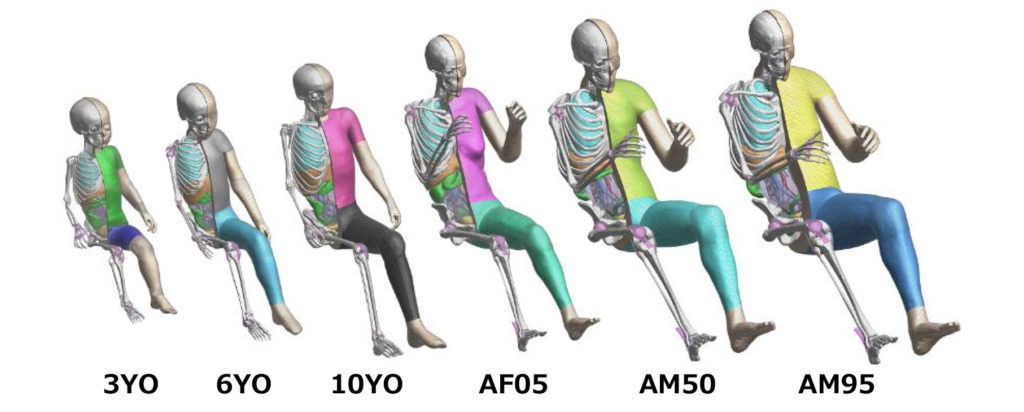

Launched in 2000, THUMS was developed in cooperation with Toyota Central R&D Labs. Since then, the virtual crash test dummy software has been through six iterations. This development has seen the system utilise detailed modelling of bones in the first version and then the face, brain and internal organs in the following years. In later iterations, THUMS added different physiques, all body muscles and models for children aged three, six and 10 years.

These updates allow the software to replicate the effect of an impact on the skeleton, internal organs and muscle tissue of different genders, age groups and physiques. Toyota claims that compared to the physical crash test dummies commonly used in vehicle collision tests, THUMS is capable of analysing impacts in much greater detail. This is because of the system’s precise modelling of the shape and durability of different human body types.

Furthermore, Toyota highlights that a software programme allows for repeated analysis of various collision patterns. This means a potentially dramatic reduction in testing costs and development lead times.

A safer society

THUMS is already being used globally by more than 100 vehicle manufacturers, suppliers, academic bodies, and research organisations. It is being applied in the research and development of a variety of different safety technologies, including seat belts, airbags and vehicle structures designed to reduce the risk of pedestrian injuries. Vehicle safety assessment organisations are also considering using the software for future virtual testing.

′Since THUMS was launched, we’ve been making improvements and working hard to better reproduce the human anatomy and expand the variations in our models’, said Seigo Kuzumaki, a fellow at advanced R&D and engineering.

′It has become indispensable to Toyota’s efforts to develop safety technologies and vehicles. We decided to make the software freely available so that more people can use it and further improve vehicle safety across the entire automotive industry. This should help reduce traffic injuries and fatalities, creating a safer society.’

Cooperative car industry

As the automotive industry continues to deal with the impact of the coronavirus (COVID-19) pandemic, the keyword among companies looks to be cooperation. Toyota has been investing in technological relationships, building up Blockchain abilities and forming a capital alliance with Suzuki. VW and Ford also recently finalised details of their collaboration, and Northvolt and Norsk Hydro too formed a joint venture to develop battery recycling capabilities.

With budgets being reviewed to establish where costs can be cut, further investment in the research and development of technologies like THUMS can best be found in collaborative efforts. Now is the time when the automotive industry can realise the potential of cooperative approaches to complex and costly projects.