Vulcan Energy Resources to supply lithium in Europe

04 October 2021

German-Australian lithium developer Vulcan Energy Resources has secured a site near Frankfurt, Germany, for a new central plant. The startup intends to supply European customers in the battery and electric-vehicle industry, hoping to significantly lower the transport footprint of the current supply chain.

Lithium is a critical component for manufacturing batteries in electrically-chargeable vehicles (EVs). Europe now sells more EVs than ever and is quickly catching up with China. With the European EV market growing at a fast pace, Vulcan Energy is looking to make an impact in the supply network and thereby lower dependence on lithium imports from outside the European Union (EU).

Processing hub

The startup says almost 80% of battery-quality lithium hydroxide chemicals come from China, but Vulcan’s zero-carbon lithium project wants to change that. The plant in the German Upper Rhine Valley, an area well-known for geothermal operations, is mapped out to become a lithium-processing hub.

‘Our “Zero Carbon Lithium Project” is unique as it aims to produce both renewable geothermal energy, and lithium hydroxide, from the same deep brine source and supply the lithium-ion battery and electric vehicle market in Europe, which is the fastest growing in the world,’ said Vulcan managing director and co-founder Francis Wedin to Autovista24.

‘A key differentiating factor for us is expected to be our ability to scale up to meet the unprecedented demand that is building in the European markets. We will be assessing further avenues to build out our future production capability, as we seek to make a significant decarbonising impact on the lithium industry.’

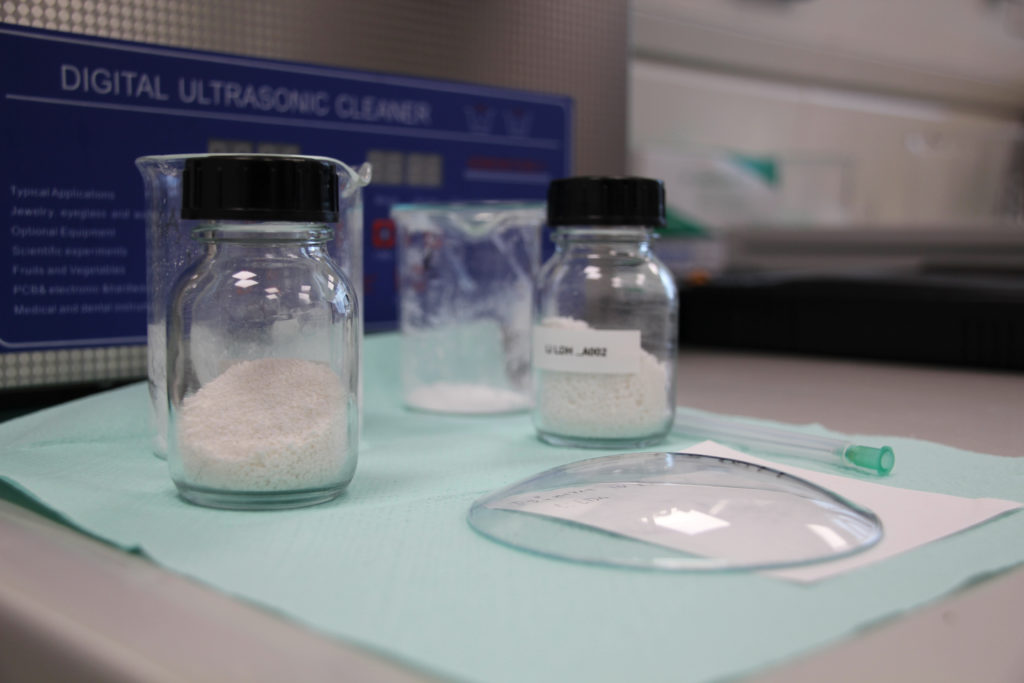

Zero-carbon footprint

Described as an energy-metals exploration company, Vulcan has a clear mission. It aims to produce the world’s first battery-quality lithium chemicals with a zero-carbon footprint. Most lithium producers engage in hard rock mining, but Vulcan Energy plans on doing things differently. The company focuses on harnessing renewable geothermal energy to drive lithium production and does so without using evaporation ponds, mining, or fossil fuels. This means its process for extracting lithium will emit no CO2, while also producing renewable power.

How does this work? Geothermal projects usually involve extracting hot lithium-rich brine from underground reservoirs. Vulcan says it will use renewable heat from its geothermal brine to drive the lithium-extraction process while also ‘decarbonising the grid’. The brine will then be reinjected into the earth – hence there are no brine-evaporation ponds, making the process more sustainable.

Focus on Europe

The company puts Europe at the heart of its business operations as the region becomes the world’s fastest-growing lithium market. Last year, the EU added lithium to its list of critical raw materials, with the union setting out a plan to become almost self-sufficient by 2025 when it comes to the supply of lithium.

Vulcan’s strategic presence in the area ensures domestic supply and ‘independence for Europe.’ It also lowers the cost of global lithium-chemicals transport while removing both the high water and carbon footprint of typical lithium extraction – which should satisfy European carmakers as they strive for carbon neutrality.

In August, Vulcan Energy signed a lucrative five-year deal to supply lithium to Renault as demand is projected to surge. Starting in 2026, Vulcan will provide 6,000 to 17,000 tonnes of lithium per year to the French carmaker from its geothermal brine deposits in Germany.

Investors have also caught on. In September, the startup raised A$200 million (€124 million), with Wedin saying the company is aiming to roll out phase 1 production in 2024 to supply the EU battery market. Meanwhile, Vulcan is keen to attract more European investors, planning a listing on the Frankfurt stock exchange.