ACC signs supply agreement for sustainably-sourced EV battery materials

28 April 2022

The Automotive Cells Company (ACC) has signed a long-term strategic supply agreement with Umicore. The materials business will provide cathode materials for the battery manufacturer’s European gigafactories.

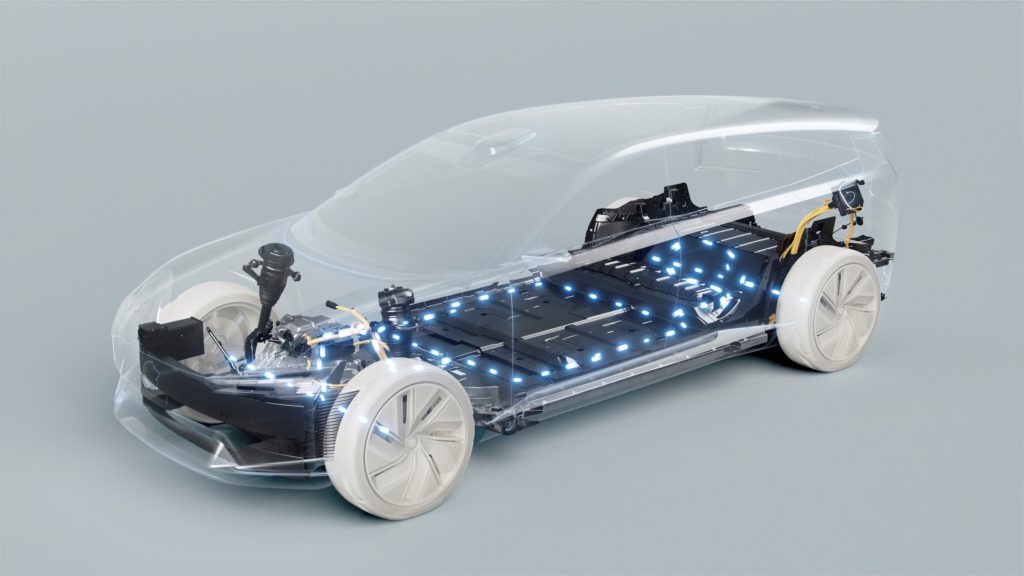

ACC is a collaboration between carmakers Stellantis and Mercedes-Benz, and energy provider TotalEnergies, together with its subsidiary Saft. The company plans to build three manufacturing facilities in Europe to provide batteries for electric vehicles (EVs). These will be located in France, Germany and Italy, close to each carmaker’s vehicle-production plants.

Global materials and recycling group Umicore will start providing next-generation high-nickel cathode materials to ACC from its greenfield production plant in Nysa, Poland. The long-term agreement will start with an annual commitment of 13GWh, with the first commercial volumes expected in early 2024.

Umicore and ACC aim to further develop their partnership, with the potential to grow supplied volumes each year, reaching at least 46GWh by 2030. This, Umicore states, will be equivalent to powering at least 500,000 EVs per year.

The agreement is the latest cathode supply deal for Umicore. The company announced a deal to supply materials to Volkswagen’s upcoming gigafactories in Europe last year.

Crucial EV supply chain

The supply of nickel has been widely debated in recent months, with the war in Ukraine leading to rising prices. This, in turn, has led to questions about the increasing EVsprices. Carmakers are looking for alternative supplies of the material, to mitigate competition from Chinese vehicle manufacturers, which still have access to a range of sources.

Although no financial details of the agreement have been disclosed, the deal means ACC has an agreed supply in place for this crucial material at a time when the reduction in volumes of nickel coming from Russia could put pressure on the industry.

‘With this important agreement, which secures the supply of a key component for the battery industry, ACC confirms its ambition to become a European leader for car batteries that allow clean and efficient mobility for all,’ commented Yann Vincent, CEO of ACC.

The partnership will see ACC provided with sustainably and ethically-sourced nickel, while giving Umicore secured access to substantial demand for its cathode materials, and the ability to further diversify its exposure to major and diverse players in the EV value chain.

‘We are very pleased to partner with ACC by enabling the fast transition to electric driving,’ added Mathias Miedreich, CEO of Umicore. ‘Our long-standing track-record in developing high-performance battery materials with industry benchmark quality levels, together with our sustainability leadership and closed-loop approach, make us a preferred partner for our customers globally.’

Battery recycling an important factor

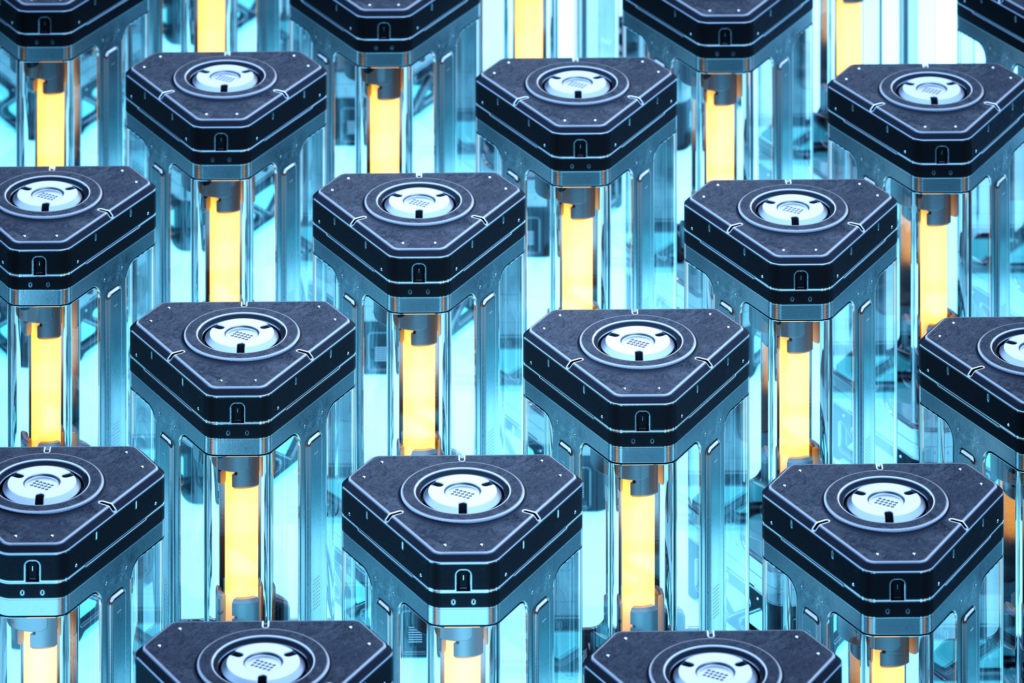

The new partnership follows an announcement earlier this year that Umicore will provide EV battery-recycling services at ACC’s pilot plant in Nersac, France.

The recovered metals will be delivered in battery-grade quality at the end of the company’s recycling process at its plant in Hoboken, Belgium. This will allow them to be re-circulated into the production of new lithium-ion batteries.

This ensures minimal waste and impact on the environment, which will be vital for the surge in EV adoption. Umicore’s facility has an annual capacity of 7,000 tonnes of lithium-ion batteries and battery-production scrap, the equivalent of 35,000 EV batteries.

Alongside material sourcing, EV-battery recycling is also likely to become a big talking point in the years ahead. The reuse of materials from spent cells will go a long way to easing some of the supply-chain pressure that EV batteries are placing on the automotive industry.