Nissan reveals production plant for electric vehicle solid-state batteries

12 April 2022

Nissan has unveiled a prototype production facility for laminated all-solid-state battery (ASSB) cells at its research centre in Kanagawa, Japan. The carmaker wants to bring the advanced electric vehicle (EV) technology to market in 2028.

‘Nissan has been a leader in electrification technology through a wide range of research and development (R&D) activities, from molecular-level battery-material research to the development of safe, high-performance EVs. Our initiatives even include city development using EVs as storage batteries,’ said Kunio Nakaguro, executive vice president in charge of R&D.

Nissan’s electric-car plans

Nissan will stop investing in internal-combustion engine (ICE) vehicles from 2023, with its long-term Ambition 2030 strategy emphasising the importance of electrification. Over the next five years, the carmaker will invest roughly €15.5 billion in accelerating this process. Advanced electric-car technology like the solid-state battery will likely become a major focal point.

If the Japanese carmaker hopes to develop and launch an ASSB-equipped EV by 2028, getting the necessary facilities up and running as soon as possible is imperative. Nissan wants to establish a pilot production line at its Yokohama Plant in 2024. The prototype facility will enable the study of the materials, design, and manufacturing processes for initial testing and manufacturing. But what makes solid-state batteries so important to the future of EVs?

Cost, density, and charge

All-solid-state batteries are expected to be a ‘game-changing technology in the race for electric-vehicle adoption. Their energy density is roughly twice that of conventional lithium-ion units, charging times are significantly shorter thanks to better charge/discharge performance, as well as lower costs due to cheaper components.

One of the major cost-creation points for an EV is its battery. Design, development, and material procurement have all contributed to a large price tag. But Nissan believes ASSBs can help bring the price per kWh down to $75 (€69) by 2028, and then to $65 per kWh from then on. This would lower the cost level of EVs to that of petrol-powered cars. Nissan hopes to introduce these ASSB price, energy, and charging benefits to a wide variety of vehicle segments, including pick-up trucks.

‘The knowledge gained from our experience supports the development of all-solid-state batteries and we have accumulated important elemental technologies. Going forward, our R&D and manufacturing divisions will continue to work together to utilise this prototype production facility and accelerate the practical application of all-solid-state batteries,’ Nakaguro said.

How does a solid-state battery work?

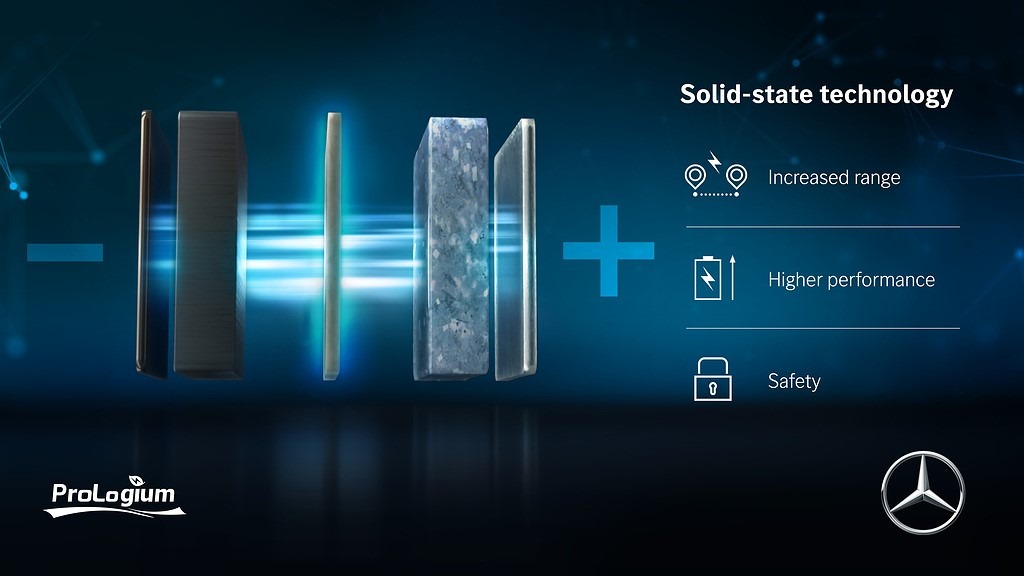

Traditional lithium-ion batteries use liquid electrolytes, with separators that keep the positive and negative electrodes apart. Meanwhile, solid-state batteries use a thin layer of solid electrolytes, which carry lithium ions between electrodes. An example of this design can be seen in a graphic published earlier this year by Mercedes-Benz.

In January, the German carmaker signed an agreement with Taiwanese battery producer ProLogium Technology to develop their own solid-state batteries. The two companies said a range of future Mercedes-Benz vehicles would be equipped with the battery cells in the coming years, probably in the latter half of the decade.