BMW, Volvo, Porsche invest in sustainable-materials company Bcomp

07 April 2022

In one of the latest pushes for greater automotive sustainability, major carmakers have invested in green-material company, Bcomp. Flax fibres form the foundation of the firm’s work. Compared to regular plastic parts, the bio-based material offers weight, energy, and emissions savings.

As sustainability becomes increasingly important to the automotive industry, carmakers are in search of the best way to create more environmentally-friendly vehicles. Apart from using less-polluting powertrains, equipping vehicles with greener parts could make a serious contribution to a circular economy. This is something companies like BMW, Volvo, and Porsche have taken notice of.

Material sustainability growth

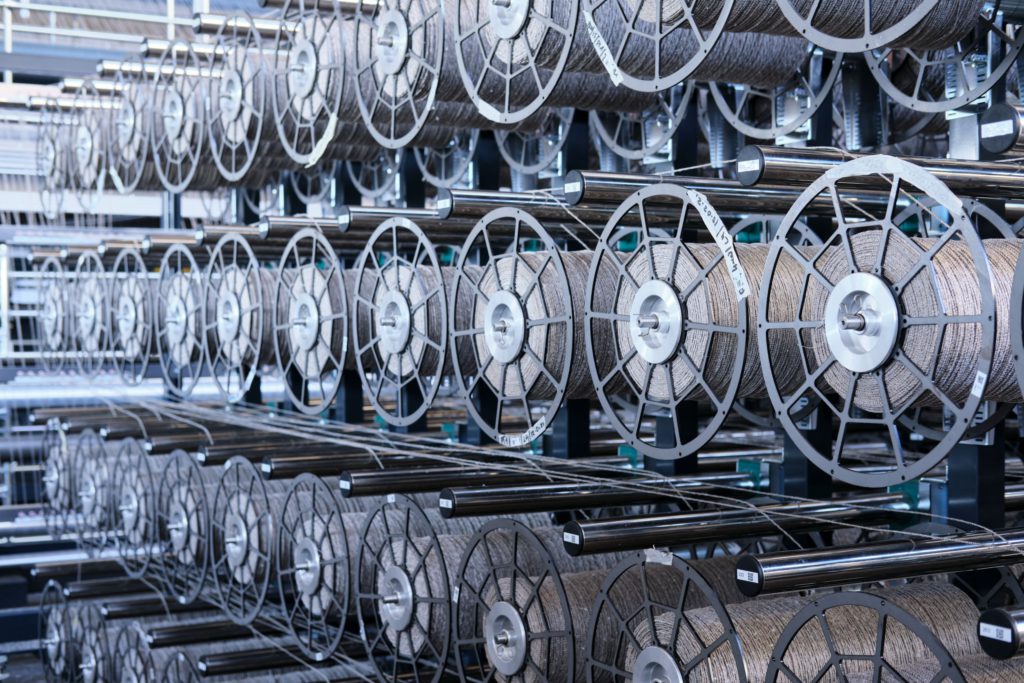

Applications for Bcomp’s products range from the automotive industry to motorsports, aerospace, and infrastructure. Its reinforcement technologies known as ampliTex and powerRibs are used for making composites with a smaller environmental impact. This is thanks to dematerialisation, renewable raw materials, weight reduction, and greater end-of-life options.

PowerRibs are inspired by leaf veins and use a 3D structure on one side of a thin-walled shell unit. This means fewer resources, costs, and consumables during production. Meanwhile, ampliTex adds a visible layer of flax fibres, which act as a carbon-neutral replacement for conventional coverings. This combination means the amount of plastic used for interior panelling can be cut by up to 70% while reducing CO2 emissions by as much as 60%.

The flax fibres used to make these products sequester carbon dioxide during their growth, as well as functioning as a rotational crop, improving soil health and subsequent harvests. As they are also indigenous to where they grow, the water and soil requirements are lower. Then once the parts are no longer needed, the material can be recycled or used for energy recovery in incinerator plants.

‘The strong interest from our targeted large-scale mobility markets is clear. Now is the time to scale our production and deploy our global strategy,’ said Christian Fischer, Bcomp CEO. ‘We are very excited to open this new chapter with the great support of our new partners, developing Bcomp as the global leader of sustainable lightweight-material solutions, and making our contribution to the circular economy.’

BMW and Bcomp

BMW invested in the natural-composite company through its i Venture arm. The German carmaker and Bcomp will establish a developmental collaboration to drive the use of renewable raw materials in components. This falls into BMW’s plans to lower its vehicle-lifecycle carbon emissions by over 40% come 2030, compared to 2019 levels. These are the kind of sustainable materials that can also be expected to appear in the recyclable i Vision Circular.

‘In order to reduce carbon emissions across its entire fleet, the BMW Group is not just focusing on the use phase – it is also paying attention to energy-saving processes during manufacture,’ said Florian Preuß, senior vice president of development complete vehicle at BMW. ‘Innovative material selection and composition are an important step here as we move towards climate neutrality.’

The firms are also planning to work more closely in the motorsport arena. Bcomp is now an official BMW M motorsport partner with the new M4 GT4 racing car. ‘Product sustainability is increasing in importance in the world of motorsport too,’ said Franciscus van Meel, chairman of the board of management at BMW. ‘So we are delighted to have Bcomp on board as an official BMW M Motorsport partner for the BMW M4 GT4 project.’

Volvo’s sustainable material investment

Using its venture capital arm, Volvo Cars Tech Fund, the Swedish car company has also invested in Bcomp. The manufacturer is currently exploring the use of natural-fibre composites in its next generation of battery-electric vehicles (BEVs). Its strategic affiliate Polestar also aims to use Bcomp’s products in upcoming models.

‘This investment is yet another example of our commitment to sustainability and strategic focus on reducing our carbon footprint,’ said Alexander Petrofski, head of the Volvo Cars Tech Fund. ‘We have a long tradition of partnering with leading technology firms such as Bcomp, as we see joint benefits in helping them to scale and develop innovative products in global markets.’

Bcomp’s materials are featured in the lower storage areas, back of the headrest, and footrest of the Volvo Concept Recharge. Outside, the front bumper, rear bumper and sill mouldings also use the company’s sustainable materials. Expected in 2024, the Polestar 5’s interior panels are also expected to use Bcomp’s sustainable technology.

‘We are very encouraged by the possibilities offered by flax composites, which is why we used them both in the interior and on the exterior of the Volvo Cars Concept Recharge,’ said Robin Page, senior vice president of design at Volvo Cars. ‘It is a material that is environmentally-responsible with a very low carbon footprint that also delivers an attractive and natural aesthetic.’

In the latest Autovista24 podcast, journalist Rebeka Shaid, editor Phil Curry, and deputy editor Tom Geggus discuss the use of sustainable materials like those developed by Bcomp.