Volvo outlines technology-laden electric future

01 July 2021

Volvo Cars Tech Moment was a showcase of near-future concepts. The online event mapped out milestones on the OEM’s journey to become a fully-electric premium car company by 2030. Boosted battery cells, data-enhanced safety, in-house developed software and simplified infotainment were signposted before Volvo’s latest concept vehicle, the Recharge, was landmarked.

Speaking at the live event broadcast from Gothenburg, Sweden, chief executive Håkan Samuelsson, explained the company was committed to building the best car in its 94-year history. ‘This is an exciting time in our development, and we will deliver on growing customer demand for pure electric cars that offer seamless connectivity, industry-leading safety standards and advanced autonomous drive.’

Boosted battery cells

No tech day would be complete without a battery update and Volvo made sure to tick the box. The carmaker is improving its lithium-ion battery technology for its second generation of electrically-chargeable vehicles (EVs), starting with the company’s first SUV built on an electric-only base. By the middle of this decade, as it introduces the third battery-electric vehicle (BEV) generation, Volvo plans to improve ranges and integrate battery packs in the floor of the car.

What does improved capacity look like in the near term? Volvo revealed it wants to increase cell-energy density by up to 50%, compared with its current market offerings. It also expects charging times to be cut nearly in half thanks to better batteries, improved software and fast-charging systems. By the end of the decade, Volvo wants to break the 100Wh/I energy density barrier, enabling 1,000km of ‘real-driving range.’

We want to constantly increase the customer benefits of driving a pure electric Volvo car.

Henrik Green, Volvo Cars chief technology officer

To achieve this, the OEM will work with Swedish battery company Northvolt, with whom it recently announced an intended joint venture. It aims to produce cells using 100% renewable energy, while working with other suppliers to do the same by 2025.

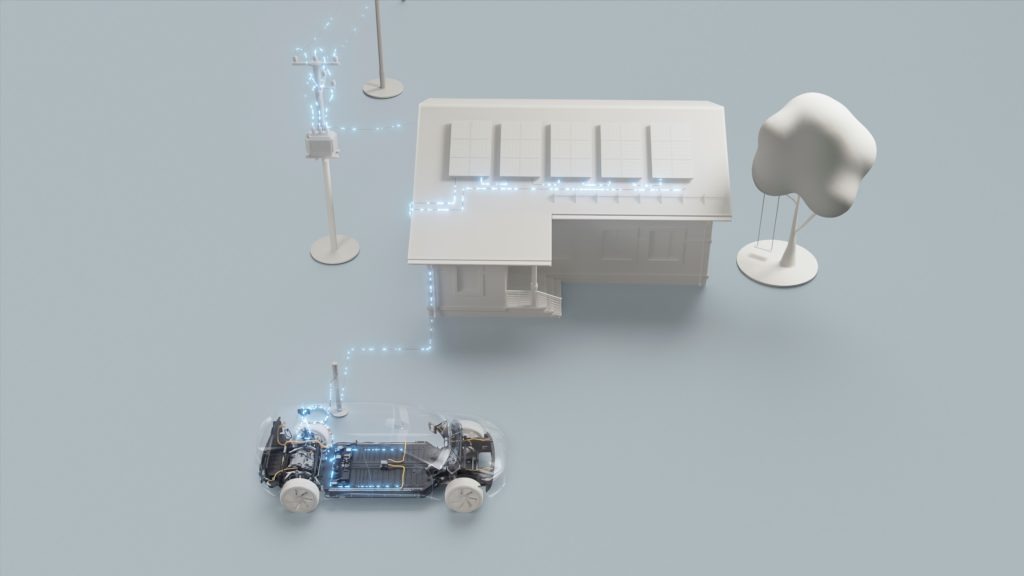

With the successor to the XC90, the company will also offer bi-directional charging, allowing the driver to offload excess power into the grid. So, drivers will be able to provide electricity when prices and CO2 emission related to energy production are at their daily peak, then recharge their car when emissions fall.

‘We want to constantly increase the customer benefits of driving a pure electric Volvo car. By simplifying the design and integration of our battery cells, we can reduce weight and maximise space, allowing for considerable improvements in battery capacity, range and charging times,’ said Henrik Green, chief technology officer.

Data-enhanced safety

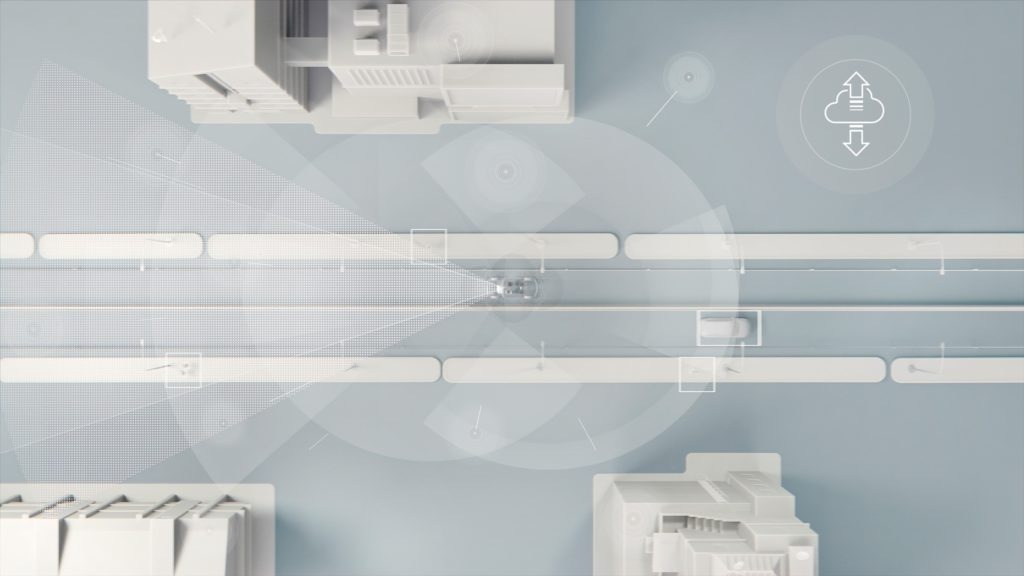

Volvo is quick to point to its legacy in safety. The carmaker has more than a few examples to point to; from the three-point safety belt in 1959 to the Side Impact Protection System in 1991 and the inflatable curtain in 1998. Taking a data-driven approach to these solutions has been fundamental to their development. The latest milestone on this journey will see Volvo’s next generation of cars processing data in real time with the consent of the drivers.

This will allow the OEM to make improvements to its vehicles in days rather than months or years. For example, engineers would be able to work on new autonomous-driver (AD) features, using real-world information generated in far greater volume than test track data could compete with. Current systems could be then be updated and new features installed via over-the-air updates.

With help from real-life data, we can speed up our development processes and go from years to days.

Ödgärd Andersson, CEO of Zenseact

Data will be sourced from numerous inputs, like Luminar’s high-resolution LiDAR, unit which will be featured as standard on the upcoming BEV SUV flagship. Processing this real-time information will be a new data factory, containing over 200 PebiBytes (225 million gigabytes) of material within the next few years. Using artificial intelligence (AI), it will be able to crunch data at record speed.

The carmaker also outlined autonomous features that it plans to roll out gradually. ‘Cruise’ capabilities will require driver supervision while ‘Ride’ functions will not. The Volvo execs did steer around the question of how these systems might be defined under the SAE ranking and instead referred back to their own supervision-based categories.

‘With help from real-life data, we can speed up our development processes and go from years to days. As real-time collection generates a lot more data, we can create better and higher-quality data sets that allow us to make better and quicker decisions on the next advancements in safety. We’re taking a giant leap to increase safety in and around our cars,’ said Ödgärd Andersson, CEO of Zenseact, Volvo Cars’ autonomous driving software arm.

In-house developed software

Volvo also announced it is taking software development in-house as vehicles become increasingly defined by their digital capabilities. VolvoCars.OS will power the next generation of BEVs, enabling faster and more flexible development. Utilising Android Automotive OS, QNX, Autosar and Linux, this new umbrella platform will incorporate various systems across the car and cloud.

VolvoCars.OS will give developers access to vehicle-sensor data, user interfaces and cloud-based features like fleet data (all subject to customer consent). This will allow them to create new services and applications for Volvo cars.

By developing software in-house we can boost development speeds and improve your Volvo faster than we can today.

Henrik Green, Volvo Cars chief technology officer

Volvo BEVs will also feature centralised computers, all operating within one system, thus reducing complexity. So rather than relying on individual control units for individual features, an increasing amount of in-house software will be used by the core-computing system. This will be introduced in a new model due to be revealed next year and will be made up of three computers. They will support each other in operation processing and artificial intelligence, general computing, and infotainment.

‘By developing software in-house we can boost development speeds and improve your Volvo faster than we can today. Just like on your smartphone or computer, new software and features can be rolled out swiftly through over-the-air updates, making your Volvo better and even more enjoyable over time,’ said Green.

Simplified infotainment

This software will also power the new infotainment system built by Volvo and Google. Returning to the touchstone of safety, the user experience will prioritise a clear split of information for the driver, presenting to what they need to know while behind the wheel. The driver screen will deliver essentials like speed and battery levels, while a head-up display shows everything at a glance. The centralised touch screen also aims to make features easily accessible, with no immediately-required system buried within menus.

Volvo’s next generation of BEVs will also enable mobile-phone connectivity via an app. This will enable features like finding and paying for charging, connecting to your home devices and remote capabilities like pre-heating and pre-cooling.

‘Our teams have spent a lot of time with Google to further develop and improve our user experience for the next generation of Volvo cars. Especially in terms of safety, serenity and simplicity, we have made great strides thanks to a deeper integration of design and technological development. We are convinced that it will allow us to create even better Volvo cars and set a new industry standard,’ said Green.

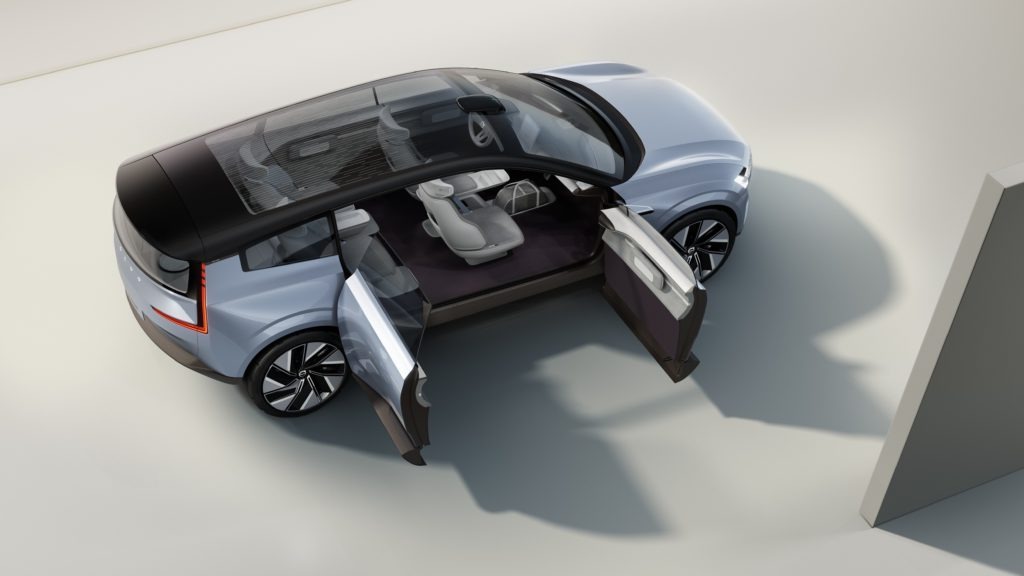

Volvo Recharge

Pulling together all the elements of Volvo’s Tech Moment was the Concept Recharge. This concept car effectively summarised the day’s concepts of electrification, safety, software and infotainment. For example, by removing the internal combustion engine (ICE), the vehicle’s proportions could be realigned on top of a flat floor. This means increase interior space and improving aerodynamic efficiency. Volvo’s first generation of EVs shared the floor design of its ICE models, meaning this was not possible.

Thrown out with the legacy floor plan, the grille has also been done away with. Instead, it is replaced with a shield structure featuring the Thor’s Hammer headlight design. These include HD technology-enabled pure graphics, which open at night to reveal the main lamp units.

‘Our Concept Recharge represents a manifesto for the all-electric future of Volvo Cars, as well as a new type of vehicle. It displays new and modern proportions that go hand-in-hand with increased versatility and shows what technology can enable in terms of design,’ said Robin Page, head of design.