Eurocell plans European gigafactory from scratch in just 12 months

17 February 2022

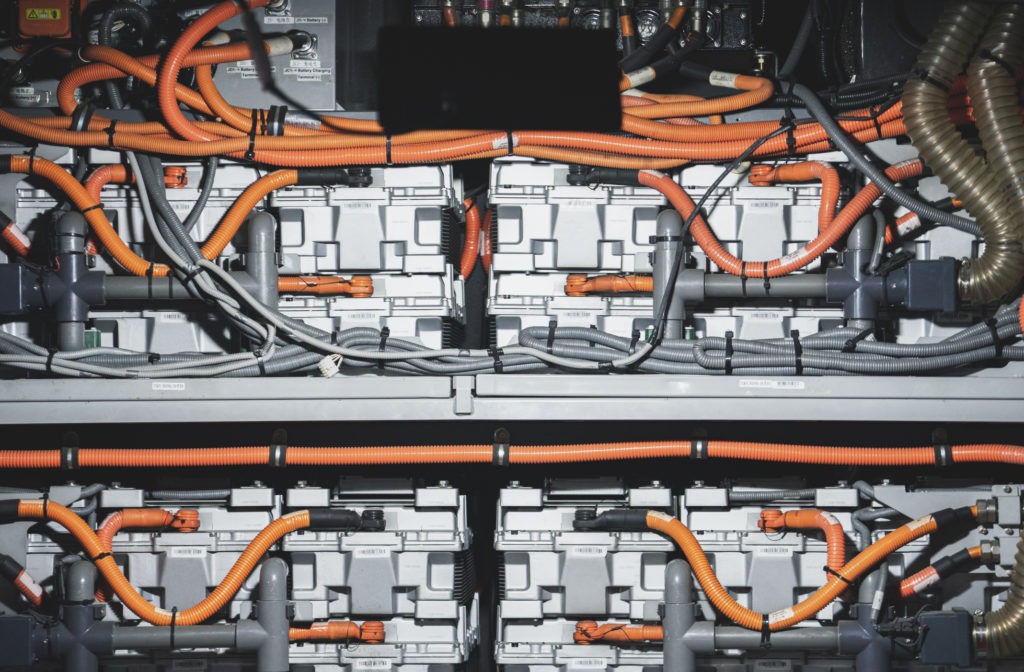

As the market for electrically-chargeable vehicles (EVs) grows, so too does the need for gigafactories – vast production lines dedicated to battery production. Eurocell is the latest company to announce plans for a site in Europe, serving automotive manufacturers based on the continent.

The Anglo-Korean battery developer is set to build what it calls its ‘first’ European gigafactory, in just 12 months. This timescale is made possible by the company’s proven battery product that is ready for scaled-up manufacturing.

With an initial £600 million (€719 million) investment planned over two phases, it intends to supply European automotive, e-mobility, and energy storage, applications. The first phase will begin producing advanced battery cells at scale by early 2023 for existing customers. In parallel, a bespoke facility will be constructed on the same site, capable of producing more than 40 million cells per year by 2025.

Three sites in contention

Eurocell has yet to pick a final location for its gigafactory. Currently, the company is assessing sites in the UK, the Netherlands and Spain. The final choice is heavily dependent on gaining the right level of government support and investment. This could potentially put the UK at a disadvantage.

The county’s government is already investing heavily in Britishvolt, a gigafactory planned for Blyth in Northumberland. It is also believed funding has been provided for Nissan’s planned site in Sunderland, while there are also plans for another gigafactory in Coventry. However, the government is open to the idea of having as many battery-production facilities as possible, as it looks to become a leader in the technology. Yet having a location on the European mainland would benefit Eurocell by cutting down on shipping costs and allowing for a more sustainable supply chain. These are also likely to be factors in the company’s decision-making process.

The company states that the selected host country will benefit from ‘the creation of hundreds of direct and indirect jobs, transferring vital skills from Korean battery experts and boosting the economy in a strategic sector crucial to achieving Europe’s net-zero ambitions.’

‘Now we are planning to rapidly expand in Europe, supplying the energy storage and automotive industries with our market-leading technologies that last longer, perform better and are 100% safe. These products can be on the market in months, not years,’ commented Recardo Bruins, CEO of Eurocell EMEA.

Long-life units

Developed in Korea, Eurocell’s batteries can last over ten times longer than conventional lithium-ion cells, the company claims. Their wide range of operating temperatures also makes them ideally suited to areas with extreme weather and without an existing grid network – perfect for the energy-storage market.

This longevity also makes the products much more sustainable, by reducing the time before batteries will need to be recycled. This would also answer a worry of some potential EV drivers, over what to do once a battery life depletes.

Eurocell’s plans will not be the last gigafactory announcement this year. With production of EVs increasing, carmakers across the continent require localised supplies of batteries, with demand likely to inspire more projects in the months ahead.