Ford and Volvo join Redwood’s EV battery recycling programme in US

22 February 2022

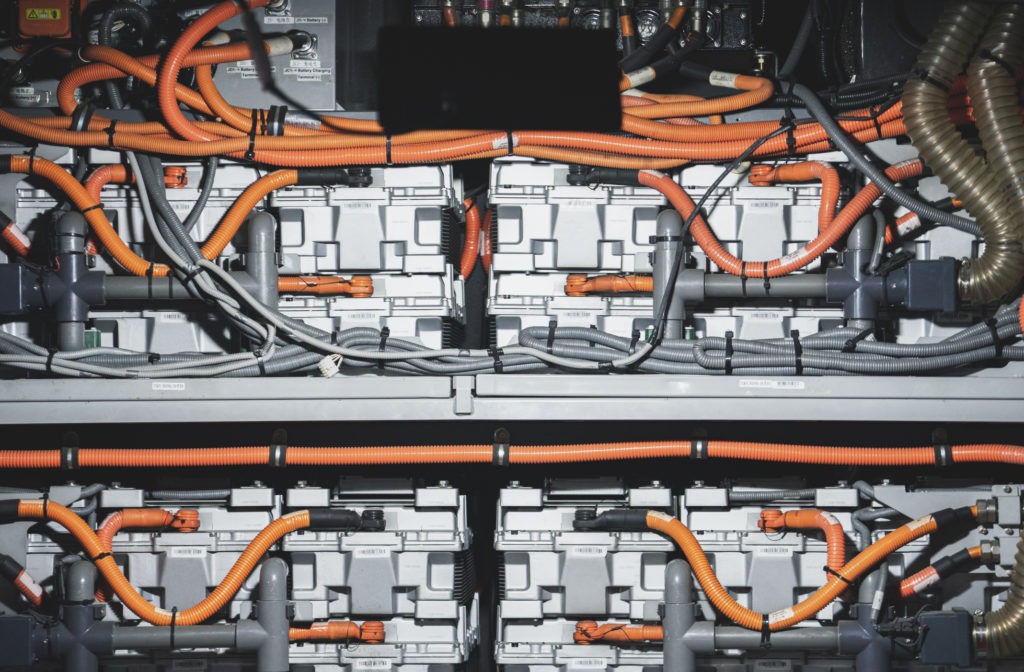

Redwood Materials, a startup founded by former Tesla CTO JB Straubel, has launched an electrically-chargeable vehicle (EV) battery recycling programme in California, with Ford and Volvo being the first carmakers to join the project. The company aims to create an efficient system to recover end-of-life battery packs from EVs.

As companies race to source materials, recycling is no longer a profitable option but a fundamental business strategy in the automotive sector. Environmental awareness is also increasing among carmakers looking to develop more sustainable battery materials. Circularity along the supply chain is the only way to clean up manufacturing, with Redwood hoping to pioneer EV battery recycling in the US. The end goal is to produce battery materials that are more sustainable and affordable.

‘To truly make electric vehicles sustainable and affordable, we need to create pathways for end-of-life battery packs to be collected, recycled and remanufactured into new battery materials,’ the startup said. ‘While the first major wave of end-of-life electric vehicles is still a few years away, Redwood and our initial partners at Ford and Volvo are committed to creating these pathways now.’

Redwood was launched in 2017 with a clear focus on establishing circular supply chains. The startup recycles scrap from battery-cell production and consumer electronics. It processes discarded goods to extract valuable materials such as cobalt, nickel, copper, and lithium. Last year, it bagged a $700 million (€618 million) investment and currently plans to expand into Europe.

Closed-loop system

As part of the recycling programme, Redwood plans to work with dealers and dismantlers in California to recover end-of-life packs. The company will then transport and recycle the batteries at its facilities in Nevada. The finished product should yield high-quality, recycled materials that Redwood wants to feed back into domestic cell production.

‘We will demonstrate the value of end-of-life packs today and how we can steadily improve those economics as volumes scale up. Ultimately, our aim is to create the most effective and sustainable closed-loop system that physics, and chemistry will allow for end-of-life battery packs to re-enter the domestic supply chain,’ Redwood stated.

The pilot programme could prove to be a game-changer as the US, similar to Europe, saw sales of EVs surge in 2021. Naturally, the focus will increasingly shift to recycling more car components, particularly batteries as these are packed with valuable rare-earths. The Biden administration hopes to unite carmakers in the country and keeps pushing for cleaner cars. It set a target of 50% of EV sale shares in the US by 2030.

Expansion

Every year, 6GWh of lithium-ion batteries – the equivalent of 60,000 EVs – are handled by Redwood. It is no surprise the startup picked California for its programme as the state is known to be one of the most progressive and EV-friendly regions in the country. While the company has worked with Ford in the past to develop a circular supply chain for batteries, Volvo is a new partner for the startup.

‘This new programme with Redwood Materials will help Ford lead America’s transition to sustainable and carbon-neutral EV manufacturing and ultimately help make electric vehicles more environmentally responsible and affordable for our customers,’ said Ford CEO Jim Farley.