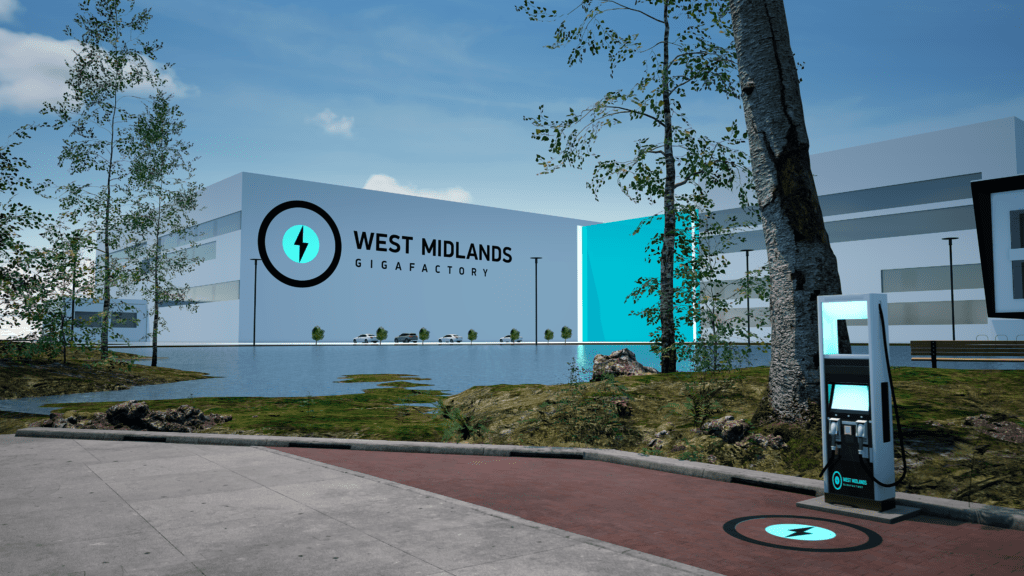

UK’s largest gigafactory to be built in Coventry?

25 October 2021

West Midlands Gigafactory (WMG) has furthered its plans to become the country’s biggest battery manufacturing site. Located in Coventry, the site could begin supplying batteries from 2025. At full capacity, it is slated to produce 60GWh of production per year.

WMG is a joint venture between Coventry City Council and Coventry Airport. Its proposed plant will be the result of a £2.5 billion (€2.9 billion) investment. In turn, it will create 6,000 new jobs directly, with thousands more predicted for the wider supply chain in Coventry and the surrounding region. An outline planning proposal for the WMG was submitted in July and the application is to be determined.

‘The West Midlands is already home to 28% of the UK’s automotive sector talent, with an established skills ecosystem and supply chain,’ said Margot James, executive chair at WMG, University of Warwick. ‘The proposed gigafactory will bring a wealth of opportunities and high skilled jobs to the region. WMG is a centre of excellence for battery technology research and development alongside UKBIC, making the region a natural home for the proposed gigafactory.’

74 football pitches

Covering over half a million square metres of space, equal to 74 full-sized football pitches, WMG is plotted to become one of the largest industrial facilities in the UK. Based at Coventry airport, the gigafactory will be adjacent to the UK Battery Industrialisation Centre, which provides a link between laboratory research and the mass production of battery technology.

Given the present emphasis on green energy, the site will have access to 100% renewable electricity, generated from a combination of solar power and other grid supplies. It will also be capable of battery recycling; in an approach it is calling ‘cradle to cradle.’

‘The West Midlands Gigafactory has a singular mission to create a state-of-the-art battery gigafactory in the heart of the UK automotive industry,’ said Mike Murray, project director. ‘The Coventry Airport site is perfectly located to do just that, being ideally positioned to supply the UK’s leading automotive manufacturers who need access to world-class batteries on their doorsteps. We need to make these advanced lithium-ion batteries where we make cars and there is no better place than in the West Midlands.’

50MW/50Mwh

Elsewhere in the UK, Pivot Power, Wärtsilä and EDF activated a 50MW/50Mwh battery energy storage system. Located in Kent, it is directly connected to the national grid and will support the integration of renewable energy sources.

This is Pivot Power’s second storage system to go live. It plans to deploy up to 40 similar sites across the UK, providing up to 2GW of flexible capacity. The venture’s first system based in Oxford, went live in June this year. It is part of ‘Energy Superhub Oxford’, a project showcasing rapid charging, battery storage, low carbon heating and smart energy management technologies.

‘The expansion of our battery storage portfolio is an important piece of the puzzle when it comes to future-proofing the UK’s energy system and accelerating a net-zero future,’ said Matt Allen, CEO of Pivot Power. ‘Through this collaboration with Wärtsilä and EDF we are creating more of the low carbon infrastructure needed to manage the integration of renewables into the grid and power our lives with clean energy.’

A sparking point

Electromobility is the result of, and the sparking point for, numerous automotive megatrends. As countries move to ban the sale of new internal-combustion engine (ICE) models, the need for essential electrically-chargeable vehicle (EV) components is paramount. In the UK, pure petrol and diesel vehicle production will reach the end of the road in 2030, hence the need for gigafactories.

But why base these sites in the country? In the last couple of years, complex international supply chains have shown their fragility, with bottlenecks of components like semiconductors putting an already struggling industry into a tailspin. So, manufacturers are looking to localise not only the production of vehicles but the components they rely on.

Ford recently committed £230 million to the electrification of its Halewood plant in the UK, which presently makes engines and transmissions. Rock Tech Lithium wants to build Europe’s first lithium converter plant in Guben, Germany. It wants to produce some 24,000 metric tons of lithium hydroxide annually, enough for 500,000 BEVs. In Italy, Italvolt recently struck a deal with ABB for it to design and engineer the front-end of its gigafactory.