Volvo joins initiative in bid to move to fossil-free steel

03 June 2022

Volvo is the first carmaker to join the SteelZero initiative, which is dedicated to increasing demand for fossil-free steel in a bid to support the shift to carbon-neutrality in the global steel industry. As part of this, the Swedish manufacturer will source 100% fossil-free steel by 2050.

The initiative also asks participants to ensure that half of steel procurement by 2030 will meet at least one of three criteria. These include sourcing certified responsible steel or low-carbon steel, as well as procuring steel from sites that are committed to reducing emissions in the long term.

Sustainable approach to steelmaking

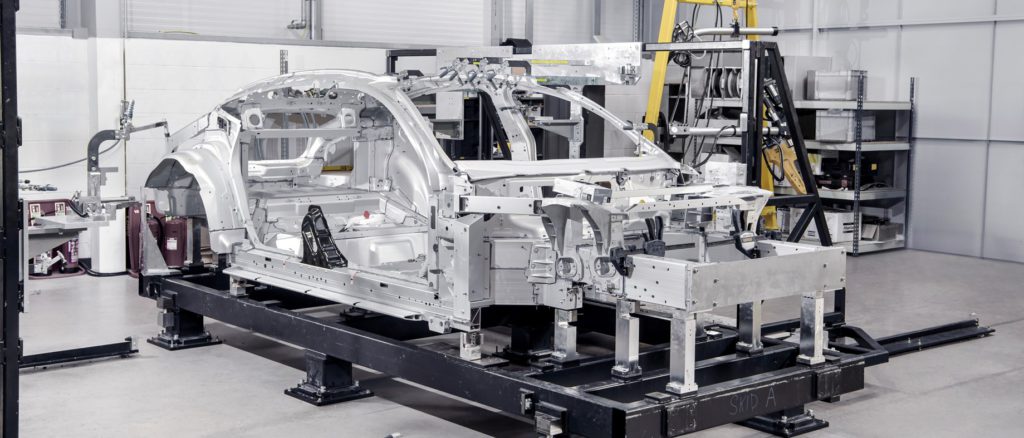

Volvo aims to be a climate-neutral company by 2040 and improving sustainability along the supply chain is key to achieving that target. Steelmaking is emissions-intensive, with global steel manufacturing responsible for 7% of all greenhouse-gas emissions. In 2021, around a third of all production-related emissions for a new Volvo car was caused by steel production.

‘A sustainable approach to steelmaking is not just good news for the environment, it is also good business as it limits our exposure to future climate risks and regulations,’ said Kerstin Enochsson, chief procurement officer at Volvo Cars. ‘By signalling our demand for responsibly sourced low- and zero-carbon steel, we aim to help drive an increased supply to our sector.’

The SteelZero initiative was launched by the not-for-profit organisation ResponsibleSteel and the Climate Group, the latter of which is known for its global EV100 initiative that supports efforts to increase the use of electric vehicles (EVs). Volvo said that through ResponsibleSteel, it would be able to access third-party verified and audited information about its steel supply chain.

Lowering emissions

Joining SteelZero is one of several steps Volvo has taken to slash CO2 emissions. The carmaker is also working with steel maker SSAB to explore the development of fossil-free steel for the automotive industry. Meanwhile, Volvo Trucks recently announced that it is the first truck manufacturer to introduce fossil-free steel supplied by SSAB.

‘Volvo Cars joining SteelZero marks an important step change in the global demand signal for low emission and net-zero steel, and a pivotal moment for the automotive industry,’ said Jen Carson, head of industry at Climate Group. ‘This sector plays a central role in driving the net-zero transition of steel.’

To lower emissions, Volvo plans to become a fully-electric carmaker by 2030. The manufacturer wants to cut the lifecycle carbon footprint per car by 40% between 2018 and 2025. This also covers the supply chain, where carbon emissions will be reduced by 25% by the middle of the decade.

Climate-neutral production is becoming the norm at Volvo. Its European car manufacturing plants run on 100% clean electricity, while its Swedish Torslanda facility is climate-neutral. In China, two sites in Chengdu and Daqing are also powered by climate-neutral electricity.

Other measures Volvo has undertaken to slash emissions include the introduction of an internal carbon price of SEK1,000 (€95) for every tonne of carbon emissions from its operations.