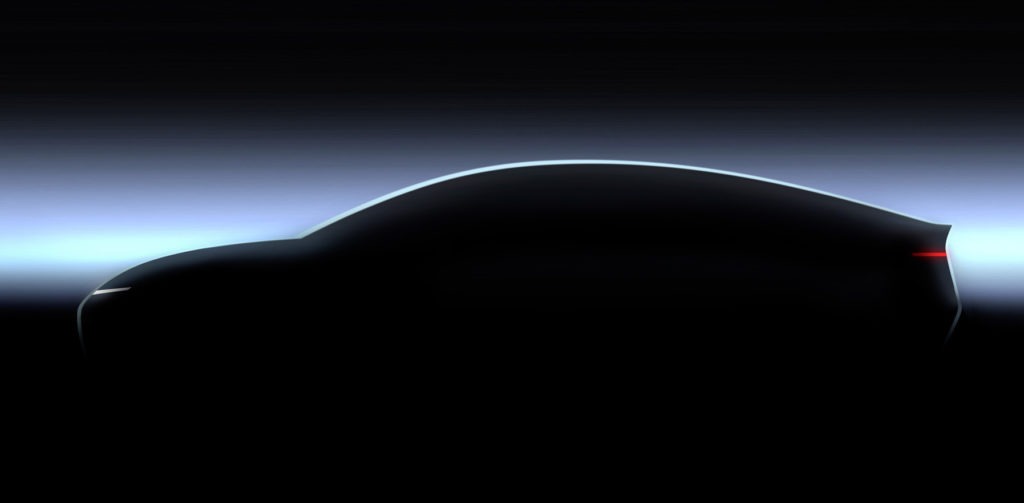

VW plans to build new site for flagship concept car Trinitiy

12 November 2021

Carmaker Volkswagen (VW) intends to build a new factory close to its German headquarters in Wolfsburg, where it plans to produce a concept car that can keep up with rival Tesla. The company said it was pushing ahead with the transformation of its main plant as it has set itself the ambitious target to become a world-leading manufacturer of electric vehicles.

The new plant would be dedicated to manufacturing VW’s Trinity, an electrically-powered sedan with an SAE Level 4 autonomous standard, which the carmaker plans to launch in 2026. Production time should only take 10 hours, with the Trinity model setting new VW standards in range, charging speed and digitalisation. The short production time matches the aspirations of Tesla, which wants to produce vehicles in 10 hours at its planned site in Grünheide, near Berlin.

The supervisory board still has to approve the plan in the coming weeks, but VW confirmed to Autovista24 that various locations in the vicinity of Wolfsburg are being considered. A final decision has yet to be made.

Bold plans

‘Wolfsburg is the symbol of Volkswagen’s global power. But the competitive pressure is increasing, not least on your own doorstep. We have to make Wolfsburg fit for the future now. That means thinking boldly, in a new and entrepreneurial way,’ said Ralf Brandstätter, chief executive of the VW brand.

The company wants to transform Wolfsburg into a centre that also focuses on the future of mobility. New models such as Trinity will be produced with fewer variants, with the hardware being largely standardised. VW said the vehicles will then have ‘virtually everything on board’, giving customers ample ‘on demand’ functions. Overall, this will reduce complexity in production considerably.

Works council chairman Daniela Cavallo welcomed the decision to build a new plant, after clashing with VW CEO Herbert Diess. The CEO had been accused of spreading fear by warning of major job cuts that faster production times might require. Diess has, however, been trying to make amends with the works council and recently told staff there were no plans to cut 30,000 jobs.

‘The plans for the new Trinity factory are bold and therefore exactly the right thing to do. We are securing employment here with the construction of a second plant in Wolfsburg,’ said Cavallo. ‘We also ensure clear future prospects and, in the long term, annual production in the high six-digit range.’

The company also wants to modernise its main plant and is testing a local 5G network for production operations in Wolfsburg, aiming to convert its sites to smart factories in the long run. If this pilot project is successful, the carmaker intends to roll out 5G technology for industrial-series production in the future. This could have a major effect on production processes, but also new business models and offers.

‘With our plan for Wolfsburg, we are giving this traditional location a binding long-term perspective,’ added Brandstätter. ‘That is good for Volkswagen, good for our employees, good for the region. It shows that transformation in Germany as an industrial location is possible. However, this transformation will only work if it is economical. To do this, we need a comprehensive location package that we will discuss with the works council.’

The German carmaker recently reported third-quarter results, cutting its outlook for deliveries as it struggles to meet demand because of the ongoing semiconductor shortage that has disrupted the automotive industry. It also lowered sales expectations, warning the risk of bottlenecks in the supply of semiconductors has intensified since the second half of the year. Deliveries for this year are now expected to be in line with 2020.