Why do major carmakers still test at the Nürburgring?

25 April 2023

For almost a century, a sprawling 20.8km long racetrack has stood as a supreme test of driving skill and mechanical endurance. Autovista24 web editor James Roberts assesses the enduring appeal of the Nürburgring as an automotive proving ground.

Since hosting its first race in 1927, the Nürburgring has become a site of automotive renown. Located deep in Germany’s Eifel mountain range, the tree-lined circuit features over 70 corners and extreme elevation changes, earning it the nickname ‘the green hell’ due to its fearsome, and deadly, reputation within motorsport. Formula One races were held at the Nürburgring, on its full Nordschleife (north loop), until 1976, when it was removed from the calendar after Niki Lauda’s fiery crash.

As well as hosting top-level motorsport events, the Nürburgring is also well known for offering members of the public a chance to drive a lap of the circuit with their own road cars, bikes and even light-commercial vehicles (LCVs). As well as the heady world of motorsport and track-day fun, this historic venue is a key testing ground for some of the world’s biggest automotive manufacturers.

Magnifying glass on vehicle development

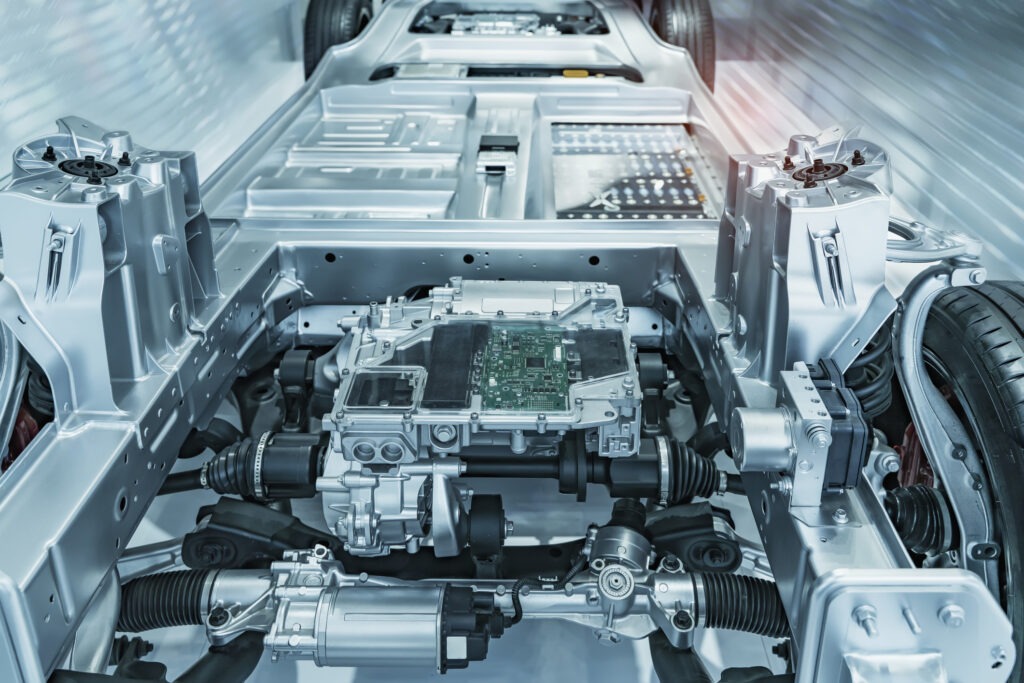

The characteristics of the Nürburgring’s Nordschleife provides carmakers with a unique setting to rigorously test a new model. From engine performance, steering and suspension, to handling and rideability, the track is a well-honed proving ground.

The steepest climb of the Nordschleife is a 17% incline, while the sharpest decline is 12%. The highest point of the track reaches 616.8m above sea level, with the lowest dipping to 320m. That makes the circuit’s elevation comparable to the Eiffel Tower in Paris.

‘Almost all renowned German and European vehicle manufacturers have development centres or workshop infrastructure in the immediate vicinity of the circuit,’ Alexander Gerhard, head of communications at the Nürburgring told Autovista24. ‘Vehicle and component manufacturers from the US and China are regular participants in the industry pool. As a rule, they also have workshop capacities and infrastructure at their disposal.’

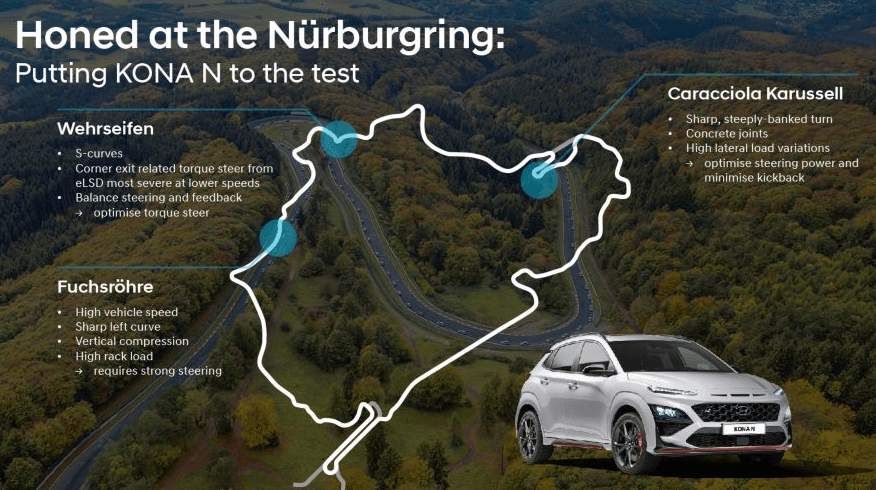

In 2011, Hyundai set up a European testing hub at the Nürburgring, and in 2013, expanded its facilities with a technical centre, comprising a 3,622 square metre test site, right next to the circuit.

Hyundai uses the facility to test vehicles from its N performance range. The Korean carmaker sees the Nürburgring as a ‘kind of magnifying glass,’ and cites the circuit’s outstanding characteristics, spread across 73 different corners, and the considerable elevation as a key attraction.

Hyundai has stated that one kilometre on the Nordschleife is equivalent to completing up to 20km on an open road, thereby concentrating the impact of testing. Every participating model drives at least 480 laps in both dry and wet conditions. Therefore, during accelerated durability testing, Hyundai N models cover a mileage equivalent to 180,000km in just four to six weeks.

‘Due to its multi-dimensional track layout with pronounced topography, the Nürburgring Nordschleife places very high demands on vehicle components such as chassis, brakes, drive, control systems and tyres,’ added Gerhard.

Automotive industry pool

Hyundai is part of the Nürburgring’s industry pool. This is a concentration of carmakers and automotive companies that have a permanent presence at the circuit, organised by the Nürburgring 1927 GmbH & Co. KG as the track’s operator.

Drives can be booked by automotive manufacturers, with testing slots taking place 16 weeks a year between March and October. As well as Hyundai, Volkswagen (VW) Group, JLR, Mercedes Benz, BMW and Honda, smaller manufacturers and startups use the circuit for testing and development.

‘The Nürburgring region has developed into a cluster for vehicle development and testing over the past decades,’ affirmed Gerhard. ‘Engineers and test drivers from many countries around the world spend a considerable period of the year in the Eifel region. Here, the car manufacturers have measurement and experience values to ensure, through suitable endurance testing, that the end customer receives a tested, safe vehicle that will last for many years and kilometres.’

Records and public relations

For many, the Nürburgring’s Nordschleife layout has become synonymous with fast lap times. Television programme Top Gear regularly used the circuit as a stage for entertaining challenges featuring everything from Ford Transit vans to supercars.

From a public relations point of view, the circuit is a proven showcase for speed. The likes of Porsche, Mercedes-Benz and McLaren all use professional racing drivers to help achieve new lap records in their latest supercars.

In 2018, a Skoda Kodiaq RS, piloted by racing driver Sabine Schmidt, clocked a lap time of nine minutes, 29 seconds, making it the fastest seven-seater SUV to complete a lap of the Nordschleife. In 2021, fellow VW Group brand Audi took five seconds off the record for a compact car with the RS3, stealing the crown from Renault’s Mégane R.S. Trophy-R.

Mercedes-Benz headed to the circuit in late 2022 to set a headline-grabbing benchmark. The German carmaker took its 1,949bhp AMG-One hypercar to the Nürburgring. With racing driver Maro Engel, it set the fastest lap for a production car at six minutes 35 seconds, slicing 10 seconds off the existing record.

‘For sportscars and performance vehicles, the Nürburgring Nordschleife is the reference track,’ stated Gerhard. ‘Like no other track in the world, it is the yardstick for the overall performance of a sportscar, and relentlessly exposes weaknesses in individual components of the vehicle.’

Lotus was recently seen putting its latest car to the test at the Nordschleife. The Geely-owned brand has been spotted testing its Envya saloon car, a possible rival to the likes of the Porsche Taycan. Porsche has also been dialling in long laps around the Nürburgring. The German luxury carmaker has been assessing updates to its 992 model, as well testing its new 911 Targa.

The Nürburgring is a place for manufacturers to tweak existing models too. Cupra has been using the facility to freshen up its Leon estate, primarily it seems to test out cosmetic upgrades to the car. The brand has also been running its Formentor coupe-SUV around the track to examine the updated bodywork before a mid-life refresh set for release in mid-2024.

Testing ground for modern mobility

Despite more carmakers turning to digital avenues such as the metaverse to develop cars and components, the popularity of the Nürburgring as a real-world testing base endures. However, some are now using it as a digital platform as well.

Several manufacturers have been spotted testing new vehicle technology at the Nürburgring, including battery-electric vehicles (BEVs). In 2022, Porsche virtually tested a 590bhp hydrogen-powered car using the circuit as a platform.

‘In the course of the increasing electrification of the automotive sector, new types of testing are in demand,’ confirmed Gerhard. ‘Development goals such as range, battery durability and other questions concerning alternative drive types are being worked on by the automotive industry at the Nürburgring.’