This week’s automotive headlines – 29 October 2021

29 October 2021

Among the countless developments in the automotive sector in October, Autovista24 is highlighting Germany’s strides with hydrogen, changes to government support for electrification in Ireland, a tech and OEM partnership for lithium-ion battery production, and a call for support from the Czech automotive industry.

TotalEnergies to invest in French EV infrastructure

TotalEnergies will allocate up to €200 million to equip more than 150 of its motorway and expressway service stations in France with high-power charge points. By the end of this year, 60 of these sites will be fitted with 50kW to 175kW plug-in points for electrically-chargeable vehicles (EVs). By the end of 2022, over 110 service stations will be equipped with 175 kW charge points. By 2023, the company hopes to have 200 stations kitted out with high-power EV infrastructure on major roads, along with 100 additional sites in urban areas, notably in the form of high-power charging hubs. These efforts form part of an ambition for TotalEnergies to offer a high-power charging station every 150km. ‘Thanks to the revenue generated from our oil and gas businesses, we can massively invest in electric-vehicle charging infrastructures and accelerate our transformation,’ said Alexis Vovk, president of marketing and services at TotalEnergies.

Germany moves to facilitate hydrogen for trucks

The German government is committing €60 million to public hydrogen-filling stations, with a particular focus on light-commercial vehicles (LCVs) and trucks. This move highlights its position among the first movers for hydrogen. It is giving priority to operators that can provide 100% renewable (green) hydrogen, with those eligible for funding receiving 80% of the total funding commitment. Also noted in October was the approval by the German government of the further enhanced prototype of the hydrogen fuel-cell Mercedes-Benz GenH2 truck for use on public roads. In April, the truck manufacturer started tests of the vehicle, which was unveiled in 2020, on the company’s test tracks. Testing will start on the B462 road near Rastatt. There, as part of the eWayBW project, freight will be electrified to test catenary trucks in operation. The project will also include comparative tests of the purely battery-electric Mercedes-Benz eActros against the catenary trucks and fuel-cell trucks from other manufacturers.

Irish government to end incentives for PHEVs

The Irish government will end its €2,500 incentive for plug-in hybrid electric vehicles (PHEVs) from 1 January 2022, as part of its 2022 budget. It also notes that all new applications for grants will only be accepted for vehicles delivered, registered, and taxed before the end of December 2021. The government updated details of its support for EVs in October and noted that any PHEV or battery-electric vehicle (BEV) above the €60,000 value threshold, which has an existing grant offer and was due to be delivered in 2021 but has met unforeseen delays due to the semiconductor shortages, will be able to get an extension to 31 March 2022. It will provide €100 million over the course of 2022, which it claims is almost double the level of funding in 2021, to support the switch to EVs and improve the charging network.

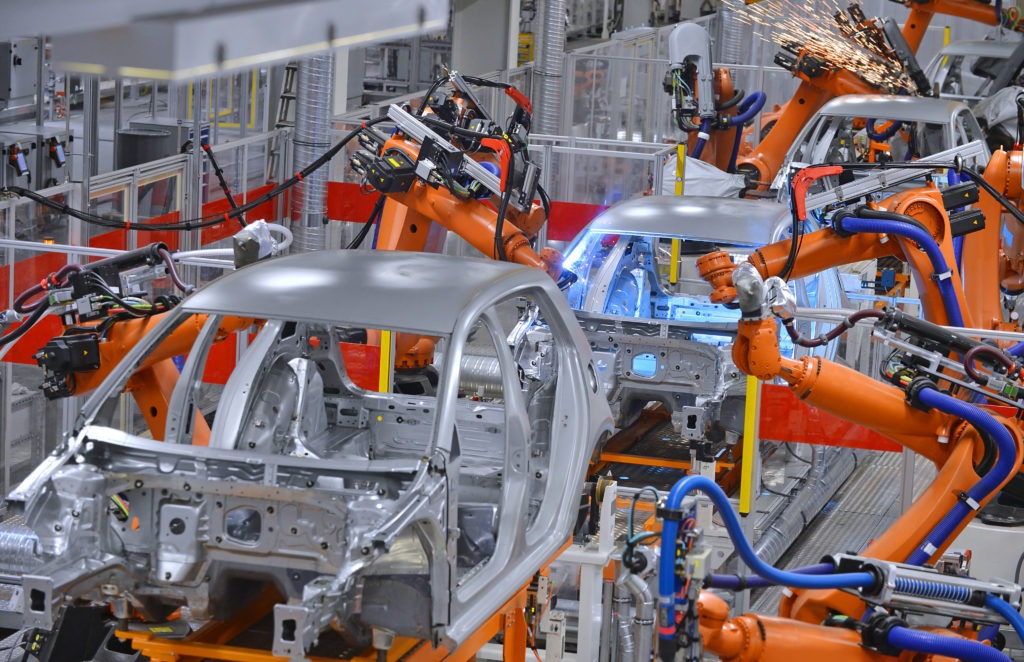

Mercedes-Benz launches EQB production in Hungary

Mercedes-Benz has launched production of its new SUV, the EQB, at its Kecskemét plant in Hungary, making it the first BEV to be built in series production in the country. From here, the carmaker will ship the model all around the world. The only exception will be the Chinese market, with a region-specific version to be made by joint venture BBAC in Beijing. Coming with a maximum of seven seats, and measuring 4.68m long, the new BEV SUV is 8cm squatter than the EQC, and 22cm longer than the EQA. The EQC utilises the GLC internal-combustion engine (ICE) framework, sitting on a large, rear-wheel-drive platform. Meanwhile, the EQB and EQA, are both based on Mercedes’ compact platform. Alongside the EQB, Kecskemét also manufactures the CLA, the CLA Shooting Brake, and the A-Class.

North American joint venture for lithium-ion battery production

Stellantis and Samsung SDI are to work together to produce battery cells and modules for North America. Starting in 2025, the partners aim to have an initial annual production capacity of 23GWh, with the ability to increase up to 40GWh in the future. The location of the plant is yet to be decided. It will fulfil the needs of Stellantis assembly plants throughout the US, Canada, and Mexico for installation in next-generation EVs. The OEM plans to invest more than €30 billion through 2025 in electrification and software development as part of its plan to be 30% more efficient than the industry with respect to total capex and R&D spend versus revenues.

Czech AIA calls for semiconductor support

The deepening chip crisis is significantly affecting the performance of the automotive industry in the Czech Republic, says the AIA, which represents automotive and allied businesses in the country. It is calling for the introduction of temporary employment support from the country’s ‘antivirus programme’, which will support the most affected companies in the supply chain. It expects that over 250,000 passenger cars will not be produced in the Czech Republic this year, and the domestic automotive industry will lose approximately CZK 200 billion (€7.8 billion) in sales due to the crisis. The AIA says the support would help businesses maintain cash flow and prepare for a subsequent restart, while supporting their ability to keep investments in modernisation at the required level.

3D printed battery cells and solid-state batteries

Blackstone Resources has announced the validation of 3D printed and solid-state battery (SSB) cells through the use of artificial intelligence. ‘The validation process involved more than 250 process parameters and 90 product parameters to verify this unique production technique with our benchmark model,’ explained Serhat Yilmaz, chief marketing officer of Blackstone. This validation will give the company access to further funding, which it will use to create further models for printing SSB cells. Blackstone states that printing cells using its patented process reduces material costs by €20/kWh through better use of inactive materials. The company points out that simulations also show production costs can be reduced by about 20% through this method.