Platinum group metals catalyse ‘cleaner’ automotive technology

05 December 2022

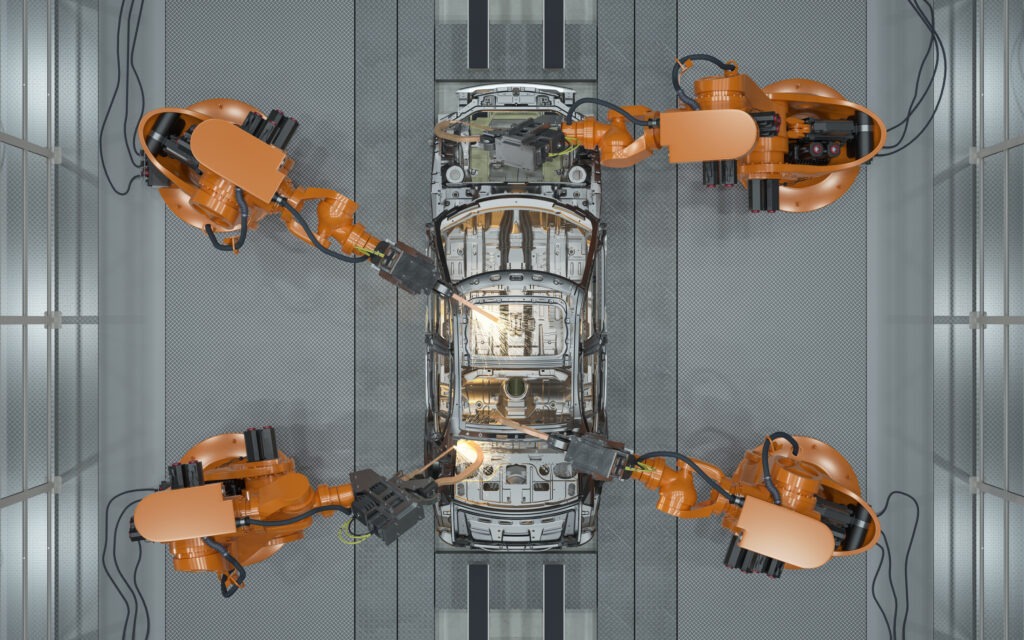

The automotive supply chain has experienced a period of upheaval in 2022. Prices of raw materials needed to build electric vehicles (EVs) have gone through the roof. Many European manufacturers are shifting their focus to electromobility, but the push to ‘clean up’ mobility also extends to internal-combustion engines (ICE).

While battery materials such as lithium remain in high demand, so do metals required to build ‘cleaner’ ICE vehicles. Platinum group metals (PGM), such as platinum and palladium, play an important role here, and could also be of use in hydrogen and EV technologies.

‘PGMs’ unique chemical and physical characteristics mean they are likely to have a range of uses in the automotive industry of tomorrow,’ Anglo American Platinum, one of the leading suppliers of PGMs, told Autovista24.

‘While there is currently no silver bullet for full decarbonisation, battery-electric vehicles (BEVs) are an important part of the new mobility mix. PGMs may help improve BEV battery performance – for example, commercialisation efforts are currently underway for palladium-enabled lithium battery technology which would improve discharge capacities and cyclability,’ the mining company added.

What are platinum group metals?

PGMs are considered rare metals, which are resistant to wear and high temperatures. Known for their catalytic properties, they have become indispensable in the automotive industry. Made up of six metals, platinum and palladium are the most important PGMs, while rhodium, ruthenium, iridium, and osmium are mined as co-products.

Many primary producers of these metals can be found in South Africa, which is home to 95% of the world’s known reserves. Due to their thermal stability, PGMs retain catalytic capabilities for a long period of time, even under extreme conditions.

The metals lend themselves to recycling. More than 95% of the PGM used as automotive catalysts can be recovered. Compared to other metals, PGMs are mined in low volumes and are also used in lower quantities.

In a study, the International Platinum Group Metals Association (IPA) found that the average PGM load for a European light-duty diesel catalyst system is 9.4 grams under Euro 6d-Temp emission standards. For a comparable petrol catalyst, it is just 3.2 grams.

‘Platinum and palladium are key components in autocatalysts that are used to clean up the exhaust. Hence, without PGMs, the internal-combustion engines would simply not operate,’ the IPA told Autovista24.

Catalytic converters

Competitive to gold when it comes to pricing, palladium – alongside platinum – can be found in vehicle exhausts, reducing toxic emissions. The metals are embedded in catalytic converters to neutralise harmful emissions in petrol and diesel vehicles. Platinum is primarily used in diesel ICEs and palladium in petrol engines.

While Europe is still more than a decade away from phasing out the sale of ICE cars in 2035, the EU is tightening emissions standards for fossil fuel-powered vehicles in the meantime. As such, palladium and platinum have become even more important automotive materials.

As catalytic converter components, the metals help to remove gases, including hydrocarbons, nitrogen oxides, and carbon monoxide. These pollutants are already covered in current EU emissions standards, known as Euro 6.

The IPA found that autocatalysts convert more than 90% of harmful gases into less harmful carbon dioxide and water vapour. It also pointed to higher fuel efficiency as an additional benefit of catalytic converters.

Supply and demand constraints

But with tighter regulations driving up demand for PGMs, the World Platinum Investment Council (WPIC) expects a deficit of platinum for vehicle exhausts.

It forecasts a 303koz (approximately 8.5 tonnes) deficit in 2023 as global platinum demand is projected to rise by 19% year on year, while supply will likely rise by just 2%. The WPIC explained that power outages and maintenance at mines in South Africa, the world’s top platinum-producing country, will restrict supply.

The organisation also projects that automotive demand for platinum will be up 12% in 2022 compared with 2021, and 11% in 2023 compared with 2022. Key drivers of this trend include higher passenger-vehicle production numbers, stricter emissions legislation, and a growing substitution of platinum for palladium.

While South Africa is a key producer of PGMs, much of today’s palladium is also sourced from Russia, which was the second-largest palladium producer in 2021, according to Statista. With the war in Ukraine, prices for the metal surged earlier this year amid fears of supply constraints.

Russia-based Norilsk Nickel, the world’s largest producer of palladium and a key producer of platinum, said it remained cautious about its production programme targets. In its latest financial report, it cited ‘newly emerged risks, which have occurred as a result of changes in the geopolitical situation.’

The OECD highlighted the severe disruptions to international markets that Russia’s war in Ukraine has caused. The organisation said it had particularly exposed vulnerabilities in the supply chain for raw materials, which are vital for industrial production and the green transition.

Carmakers have ramped up efforts to reduce the use of palladium due to the war in Ukraine, switching to platinum instead. The metal could keep growing in significance as the automotive industry shifts to cleaner mobility – that is because it has its uses beyond catalytic converters, taking centre stage in hydrogen-powered vehicles.

Catalysing hydrogen

Platinum is currently used in hydrogen fuel cells, with industry bodies expecting increased automotive demand. In fuel-cell vehicles, platinum functions as a catalyst, enabling chemical reactions.

Compared to an ICE model, hydrogen-powered vehicles use roughly double the amount of platinum. Anglo American Platinum found that even a small percentage of FCEVs can significantly impact the demand for the metal.

‘In hydrogen fuel cells, platinum acts as a catalyst, allowing a fuel cell’s hydrogen and oxygen reactions to release electricity efficiently while being stable enough to withstand the complex chemical make-up and high electrical current density of a fuel cell,’ Anglo American Platinum told Autovista24. ‘There is also evidence palladium could work alongside platinum as another catalyst of future hydrogen fuel cell technology, but further research is required.’

Major carmakers – from BMW to Renault – have hydrogen projects in the works, believing the technology could be a sustainable option alongside BEVs. This month, BMW started small-series production of the iX5 hydrogen model, with a test fleet due for production in spring 2023.

Although hydrogen-related platinum demand is relatively small in 2023, it is forecast to grow significantly in the medium term. As such, platinum group metals will continue to play their part in global decarbonisation efforts in the automotive industry.