Continental launches car tyres made with recycled PET bottles

18 April 2022

Automotive supplier Continental wants to make its car products more sustainable, with the German company being the first manufacturer to launch volume production of tyres made with recycled polyester – sourced from plastic bottles.

The car supplier developed a new process to produce the high-performance automotive material, which will be used in a range of selected summer and all-season tyres. The novel product will replace the traditional polyester in the carcass of the tyres, with one set using material from around 40 recycled PET bottles. They are available in several sizes.

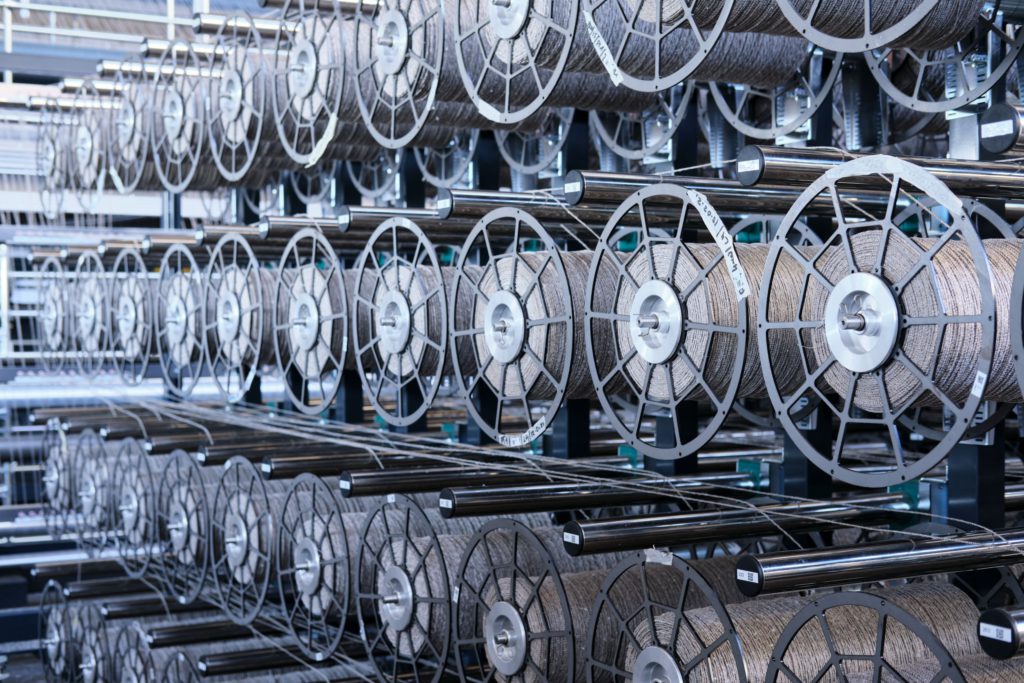

The company first revealed the technology behind the tyres last year. Dubbed ContiRe.Tex, it uses polyester yarn, retrieved from used PET bottles, without applying intermediate chemical steps. While other car suppliers also rely on technologies to process PET bottles into polyester yarn, Continental says its technology is more efficient than standard methods.

The bottles originate from regions, where closed-loop recycling is not the norm. These then get sorted, cleaned, shredded, and granulated to be spun into polyester yarn. Produced at a plant in Portugal, the tyres will be marked to let consumers know they contain recycled material.

Sustainable materials

‘We only use high-performance materials in our premium tyres. From now on, these will include polyester yarn from PET bottles, made in a particularly efficient recycling process,’ said Ferdinand Hoyos, who heads Continental’s tyre replacement business in Europe, Middle East, and Africa (EMEA).

‘We brought our innovative ContiRe.Tex technology to the production stage in just eight months. We are constantly expanding the share of renewable and recycled materials in our tyres. By 2050 at the latest, we want to use only sustainable materials in our tyre production.’

Automotive textiles made with polyester yarn obtained from recycled PET has been in use for a while, especially in passenger and light truck tyre manufacturing. Continental says that the cords absorb the pressure of the tyre and remain stable under high loads and temperatures.

During the 2021 IAA Mobility event in Munich, the tyre manufacturer introduced its ‘green’ tyre concept, which relies on renewable and recycled raw materials that make up more than half of the material used. It also includes polyester from recycled plastic bottles.

Greener tyre production

The German automotive supplier is exploring alternative, and more sustainable materials for tyre production, with the aim of making the product more energy-saving and environmentally friendly.

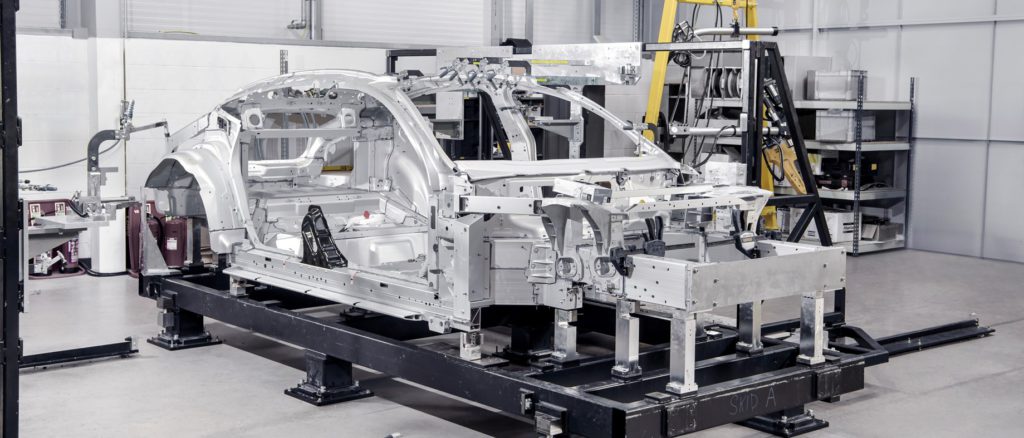

Continental has been researching the industrial use of dandelion rubber for more than a decade. It also cooperates with the so-called innovation network for advanced materials (INAM) to study more sustainable material, with a clear focus on recyclability. The company supplies its ‘sustainable tyres’ to Volkswagen, which the carmaker will use it in the ID. Life concept car.

One of Continental’s rivals, Michelin, is also heavily researching sustainable materials that it can use in tyre production. The France-based manufacturer is looking into making butadiene, a key component in the synthetic rubbers used to make tyres, more sustainable by integrating biomass such as waste wood, rice husks, and corn stover. Michelin also said that 4.2 million tonnes of wood chips could be added to its tyres each year.

The sustainability of tyres could become increasingly scrutinised in the coming years. Not only are the materials used in their production likely to spark debate, but the particulate matter caused by their wearing is also a problem the industry needs to address.

Heavier electric vehicles coupled with less durable tyres can lead to increased particulate matter, an issue the automotive industry has been grappling with since the Dieselgate scandal in 2015. Already, tyre suppliers are looking at producing specialised products for battery-driven cars, while Audi is developing filters to prevent tyre particulate matter from reaching the water table.