Exclusive interview with Polestar: ‘We want to be the most progressive car brand’

21 March 2022

Autovista24 journalist Rebeka Shaid explores Polestar’s plans in an exclusive interview with Sander Jahilo, circular lead, sustainability at the company.

Polestar wants to do things differently. A brand with Swedish roots, the carmaker has a non-conformist streak compared to its parent company Volvo, which spun off Polestar back in 2017 along with its Chinese owner Geely. Often dubbed a Tesla challenger for its innovative and all-electric approach, it has quickly built a name for itself as a premium brand. But there is more than meets the eye.

Its high-performance battery-electric vehicles (BEVs), equipped with the latest technology, certainly demand attention, and reflect the company’s adventurous spirit. While the brand’s planned flotation will turn it into one of the most valuable electromobility startups out there, Polestar is not about the hype but takes a no-nonsense attitude. This applies particularly when it comes to sustainability, a key focus and strategic pillar for the carmaker.

Zero carbon?

The luxury carmaker has won over notable investors for its environmental-focused outlook, including actor turned green activist Leonardo DiCaprio. As the company has pledged to build a ‘sustainable future for all’, it is centring its attention on four core areas: climate-neutrality, circularity, transparency, and inclusion. To prove that it is serious about sustainability, Polestar plans to launch the Polestar 0 by 2030, a high-tech climate-neutral car.

‘Our aim is to position ourselves as the most progressive car brand out there,’ said Jahilo, who joined the company in May 2021 in a newly created role. ‘And we strive to do that through benchmarking with other automakers to see what they are doing. We have made assessments on how they approach circularity, seeing that there is not a very high level of awareness of how big companies are reporting and creating strategies on circularity.’

The Polestar 0 is a good example of how to apply a circular design to car manufacturing, making use of circular batteries, recycled materials, and renewable energy across the entire supply chain. ‘Circular economy in our definition encompasses all of the sustainability focus areas: from biodiversity and water consumption to recyclability,’ said Jahilo.

The nine Rs

But the carmaker is moving beyond zero carbon and wants to go the extra mile. Jahilo stressed all the ‘nine Rs’ of circularity are part of the company’s sustainability strategy: refuse, rethink, reuse, repair, refurbish, remanufacture, repurpose, recycle, recover.

‘The Polestar 0 is focusing on the carbon footprint of that vehicle,’ he said. ‘But the problem is not only with carbon that we have nowadays. It is also [about] the depletion of natural resources. If we cannot reduce the amount of material that goes into the cars, or we cannot increase the recyclability of those materials in the cars, then we are still digging a hole for ourselves, even if it is carbon-neutral. We should not see carbon neutrality as the only goal we need to work with.’

Jahilo is currently in the process of developing a circularity roadmap for the organisation. He said the company is serious about the environmental impact car manufacturing has from chemicals and ‘everything that happens up- and downstream.’ The carmaker does not shy away from being open about its greenhouse-gas emissions and wants to be transparent about the methods and processes it uses to achieve climate-neutrality by 2040.

No greenwashing

This is arguably a more novel approach to tackle serious climate-related issues, and Polestar’s Life Cycle Assessment (LCA) report is clear about the carbon footprint of its products, with Jahilo calling the document a major milestone for the company.

‘We want to make as much as possible of our information public so that it can be scrutinised by NGOs or other companies on what we report, and then to define what is circular and sustainable,’ said Jahilo.

‘We know other carmakers are doing LCAs, but not all of them are publishing those results. We want to show that regardless of what your result is, it is good for your customers and NGOs or whoever wants to scrutinise that data to see what the status is, so that you can start improving on that and not just use greenwashing to your advantage.’

Greenwashing is a practice used by companies to make unsubstantiated claims about their products, in an effort to sound sustainable – when clearly, they are not. While there are still plenty of businesses out there using misleading information to appeal to environmentally-conscious customers, Polestar is not one of them.

The carmaker wants to set new standards on the sustainability front, and that means putting pressure on suppliers to ensure they comply with the company’s stringent requirements. Jahilo emphasised Polestar is trying to integrate sustainability into the workflow of how it operates, but he admitted it takes time to do so because of the many procedures and structures involved. Building cleaner cars is not straightforward, but he is on the job.

‘We are not manufacturing our own cars in our own plants currently, so this coordination between all the stakeholders will be broadly my main focus, to talk with the innovators, the startups who have interesting ideas and then people within our supply chains and internally as well,’ he said.

Sustainable materials

The automaker is working with plenty of cutting-edge startups, some of which might not have scaled up enough to develop their products in mass quantities but still show promising business models. One particular area Polestar is looking at when collaborating with these companies is sustainable materials.

Volvo made a big announcement last year, saying it was only going to use vegan leather in the future, which will be made from bio-based and recycled sources that might still contain PVC, i.e. plastic. Polestar wants to go a step further.

‘We want to find a vegan leather alternative that is sustainable, not using PVC,’ said Jahilo. ‘I do not think we want to continue using polymers and plastics if they are fossil-based forever. There might be something that is fully biodegradable, bio-based and extremely durable and strong that might emerge in coming years.’

The company sources natural and plant-based fibre that is recyclable and can be used in car interiors. These are lighter while still being durable. Discarded fishing nets are also of interest to Polestar as they are made of high-strength nylon, which is recyclable and can be integrated into carpets and other surface materials.

‘That is a great way of not just recycling and using old material, but also protecting the marine ecosystems because the fishing nets constitute 20% of the whole marine plastic pollution,’ said Jahilo. ‘If we can create a market for that material to bring that out and recycle it, that is a really good step forward.’

Traceability via blockchain

The EU Commission recently adopted a proposal to push for corporate sustainability along global value chains, which will have a direct effect on European carmakers like Polestar once it comes into force. Although the company has many sustainable corporate practices in place, it still faces challenges in improving its environmental footprint – not least because of the main component found in its luxury cars: batteries.

‘Batteries do indeed pose a challenge for the electric-vehicle makers,’ said Jahilo. ‘We know from our own LCA that the battery is around one third of the whole car footprint. So, if you compare it to a regular internal-combustion engine (ICE) car, the initial footprint of the car as it leaves the factory is higher for an electric car because it has the additional battery that the ICE car does not have.’

Of course, this can be balanced out over the whole lifecycle of an electric vehicle (EV), especially when powering up with renewable power. Ethical mining for rare-earths found in batteries is critical. Polestar is setting out safeguards to prevent adverse effects from mining and is closely tracing the impact of water consumption in those mining areas. The marque is also monitoring the working conditions of miners, as well as the environmental impact on local biodiversity.

Blockchain can aid the effort to clean up the supply network. Polestar partnered with supply-chain transparency provider Circulor to track minerals and materials via blockchain – a system that provides the infrastructure to track CO2 emissions of these resources.

‘It is hard to trace back all of the materials in a battery to their respective mines. But we have already done this through our traceability scheme with Circulor to trace cobalt from mine to the final product. And we are going to be adding more minerals into [the scheme],’ added Jahilo.

But he also had words of caution when it comes to mining for minerals, even as the industry cleans up its act. ‘The mining industry will face challenges in the coming future. Even if it becomes carbon-neutral, it has to mitigate the impact on land and water ecosystems.’

Tech, tech, tech

Vehicle production cycles are long, and it usually takes five years to get a car on the road from the early design phases to the finished product. Polestar plans to launch one car per year up until 2024, giving the company time to meticulously plan ahead and integrate the latest technology. Its advanced engineering team is dedicated to exploring cutting-edge innovation to drive up performance.

‘There are so many areas where technology can help us, starting from generative design, which is essentially artificial intelligence,’ said Jahilo, also referring to controlled computer-aided design. ‘You put in the parameters that are requirements of what your component must do in terms of physical or crash dynamics characteristics, and then the software tries to build that part in as efficient a way as possible, using the least amount of material, the least amount of joints.’

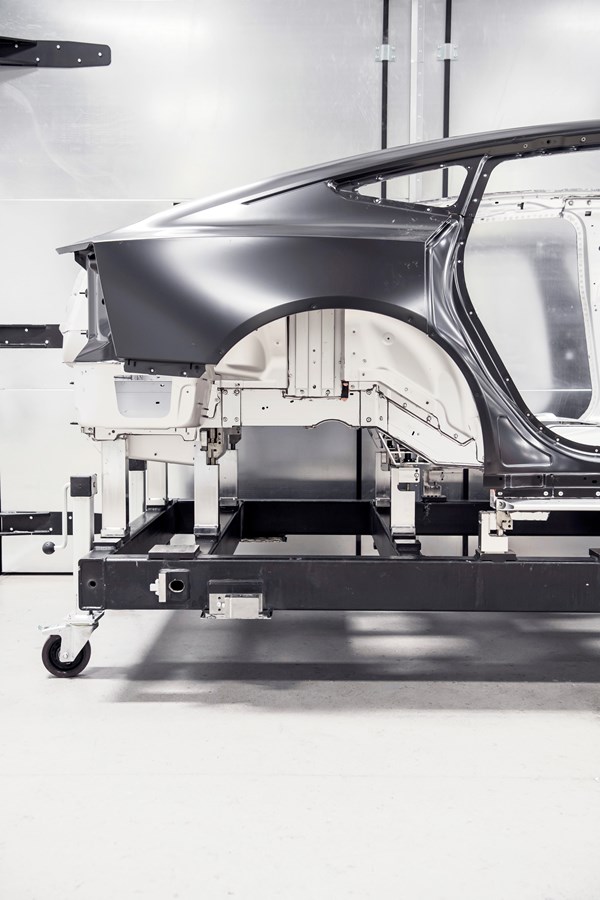

In 2024, the carmaker aims to roll out the Polestar 5, a four-door grand tourer, which will showcase the brand’s future vision regarding design, technology, and sustainability. It will feature a new bonded-aluminium platform that is defined by its light weight and rigidity, offering performance and environmental advantages.

Bonded aluminium has usually been restricted to low-volume performance cars as it involves intensive labour. But Polestar’s 280-strong team of engineers in the UK has resolved the issue by creating a new and faster manufacturing process that moulds the body and platform in unison.

This kind of innovation and technology is what will drive sustainability forward. ‘We see a lot of potential for technology to help us along. I think most of the ways we can achieve our circularity goals are technology-focused,’ said Jahilo.

More to come

Polestar plans to make the future of mobility more environmentally friendly. But can a car really be sustainable, and how long would we have to wait to see that happen? According to Jahilo, it would be possible to have circular cars roaming around the streets now, but there is a problem.

‘The market itself is not demanding these products enough,’ he said. ‘A car that is made of fully-recycled materials would probably not have the same performance and the same appeal to many users – because the materials used will not be as fancy or not have the aesthetic appeal that people expect.’

While it might still take decades to make transportation truly sustainable, the future of mobility will be carbon-neutral and gentler on resources, Jahilo believes. Polestar wants to see more specialisation in the recycling of all the materials used in a car. Closed-loop recycling could then be applied to a range of materials, such as aluminium and steel, without down-cycling the components. Until that happens, Polestar will be a promising carmaker to watch.

‘We have a lot of internal milestones that we do not publicly talk about,’ said Jahilo. ‘There will be a lot to come in the coming year.’