German government invests in lithium-sulphur vehicle-battery project SoLiS

09 August 2021

The German Federal Ministry of Education and Research (BMBF) is funding five partners from science and industry with a total of nearly €1.8 million to progress development of vehicle batteries powered by lithium sulphur.

The ‘SoLiS’ (development of lithium-sulphur solid-state batteries in multilayer pouch cells) research project started in July 2021 and is led by the Fraunhofer Institute for Material and Beam Technology (IWS), based in Dresden, Saxony. The aim of the SoLiS project is to transform the research concept of lithium-sulphur batteries, with multiple electrode layers, into an industrial application.

In solid-state batteries, solid electrolytes transport lithium ions between the positive and negative electrodes. ‘In combination with new storage materials, they are accordingly the key to safe battery cells with high-energy density. After all, liquid electrolytes lead to undesirable side reactions in lithium-sulphur batteries, which have so far resulted in a short cell life. The challenge is to place the storage material sulphur in close contact with electrically-conductive carbon and the ion-conducting solid electrolytes,’ commented Fraunhofer.

‘Thanks to high storage capacities and low material costs of sulphur, this cell technology potentially enables the construction of very lightweight and cost-effective batteries. However, there is too little data on application-relevant prototype cells, making it impossible to evaluate the technology as of yet,’ the institute added.

Fraunhofer is responsible for the coordination of the SoLiS project and provides ‘know-how on innovative processes for the fabrication of electrodes and prototype cells’ and is joined by four partners.

The Technical University of Dresden works on the cathode composite materials and a suitable electrode design, and scientists at the Westphalian Wilhelms University in Münster are investigating solid electrolytes and their transport properties in lithium-sulphur batteries. The Justus Liebig University in Giessen contributes its experience and expertise in characterising interfacial phenomena in solid-state batteries and evaluates possible advantages of additives, whereas Schunk Kohlenstofftechnik GmbH is responsible for the production of carbon additives and any relevant composite materials.

Further Fraunhofer initiatives

Fraunhofer already works with German vehicle-battery manufacturer Varta to compete against Asian manufacturers and establish a domestic market for batteries.

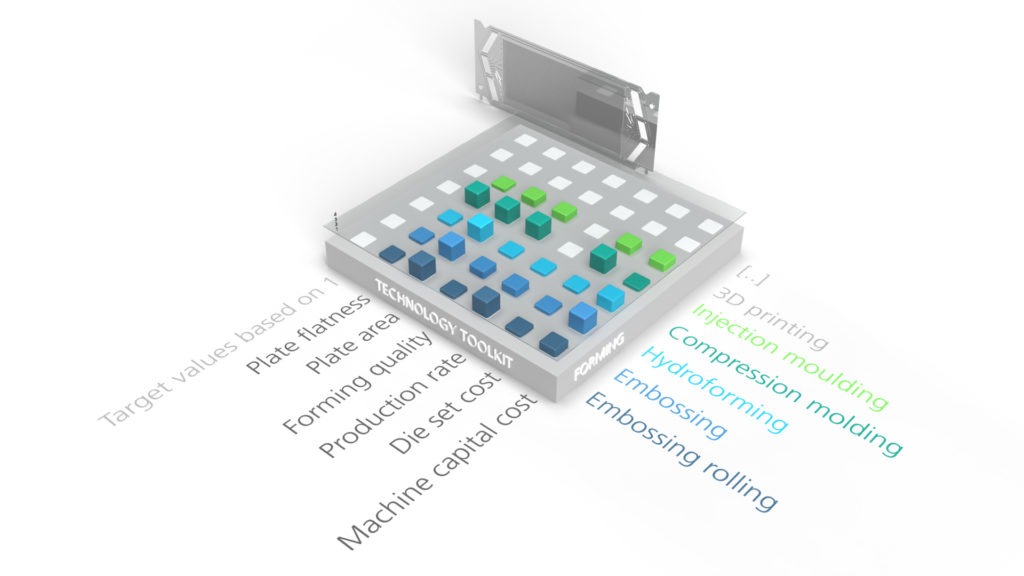

Furthermore, as the interest and need for hydrogen fuel cells grow, the Fraunhofer Institute for Machine Tools and Forming Technology (IWU) and the Fraunhofer Institute for Production Technology (IPT) are providing their expertise in the field into a shared virtual-technology toolkit.

According to the institutes, there is a need for cost-reduction in the production of the bipolar plates within fuel cells. These are a central element of fuel cells and control the supply of hydrogen and air, as well as the extraction of steam and energy.