GM signs multi-year cobalt supply deal with Glencore

14 April 2022

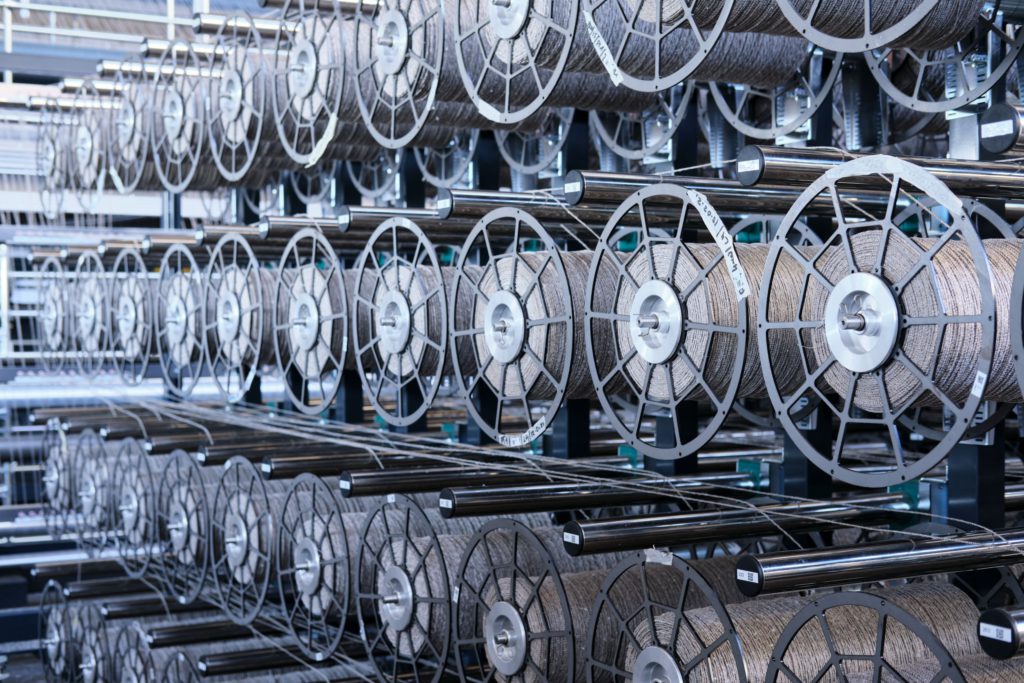

General Motors (GM) has signed a multi-year, cobalt-sourcing agreement with Glencore. The rare-earth mineral is an important electric vehicle (EV) battery material, used in cathodes.

Cobalt will be supplied from Glencore’s Murrin Murrin mining and processing operation in Australia. The material will be put to work in GM’s Ultium batteries, helping power electric cars like the Chevrolet Silverado EV, GMC Hummer EV, and Cadillac Lyriq.

Battery-building ecosystem

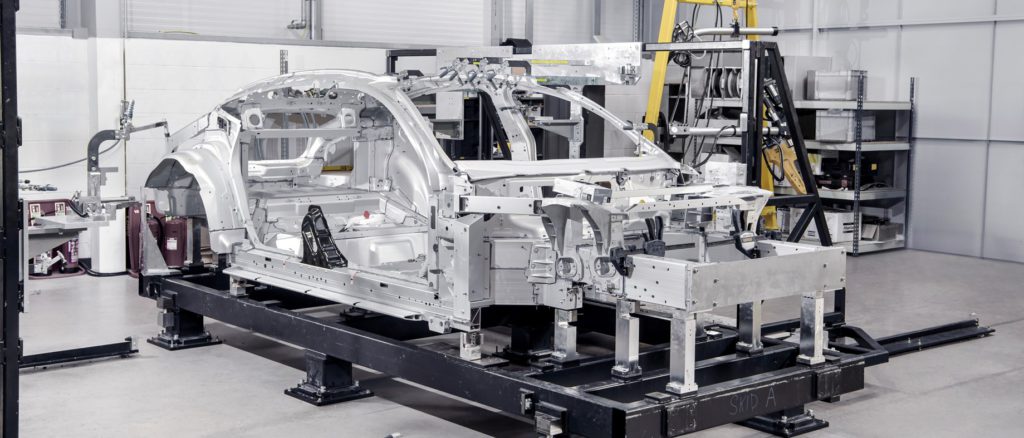

By the end of 2025, GM wants to wield the capacity to build one million electric vehicles in the US. It also recently announced it is joining forces with Honda to develop a series of affordable EVs. By 2027, a new platform spawned from this partnership will act as the foundation for the global production of millions of electric cars. But to achieve these manufacturing milestones, a steady supply of sustainably sourced materials is required, and cobalt is no exception.

This is creating space for new supplier-manufacturer agreements, like the one between GM and Glencore. The carmaker and the supplier are keen to emphasise a commitment to creating strong, sustainable, and resilient supply chains. Both companies are members of the Responsible Minerals Initiative (RMI). Glencore’s Murrin Murrin operation is also compliant with the OECD-aligned Responsible Minerals Assurance Process.

‘GM and our suppliers are building an EV ecosystem that is focused on sourcing critical raw materials in a secure sustainable manner,’ said Jeff Morrison, GM vice president of global purchasing and supply chain. ‘Importantly, given the critical role of EVs in reducing the carbon footprint of the transportation sector, this agreement is aligned with our approach to responsible sourcing and supply-chain management.’

‘We are delighted to announce this collaboration and support General Motors in delivering its electric-vehicle strategy,’ said Ash Lazenby, Glencore US cobalt marketer and trader. ‘Future facing commodities like cobalt play a pivotal role in decarbonising energy consumption and the electric vehicle revolution. Glencore is already a leading producer, recycler, and supplier of these commodities, which underpin our own ambition of achieving net-zero total emissions by 2050.’

Counting on cobalt?

While cobalt does play an important role within many electric vehicle batteries, it is not a bountiful material, only accounting for some 0.001% of the earth’s crust. But, when added to the cathode of a lithium-ion battery it can improve energy density and longevity, while also boasting heat-resistant properties.

As electrification surges within the automotive industry, the demand for cobalt has been building correspondingly. However, the ethics of sourcing this rear-earth mineral has come under the spotlight in recent years. It is mined in regions of the world often overcast by the shadows of war and poor human-rights records. This has led to some manufacturers trying to tighten up their supply chains. Volvo wants to ensure the ethical sourcing of cobalt via transparent record-keeping in the form of blockchain supplied by Circulor.

Other companies are attempting to avoid the material altogether, by re-examining and re-designing how they build batteries. Electric-adventure vehicle firm UBCO recently announced a partnership with Chemix, an AI-powered battery developer. The two companies hope to commercialise cobalt-free lithium-ion battery technology. ‘We are delivering positive impact quickly and this partnership will help to provide a solution to three huge challenges in the industry – increased battery energy, longer range, and a cleaner supply chain,’ said Colin Godby, chief product officer for UBCO.