How are car companies decarbonising vehicle lifecycles?

06 April 2022

Car companies are on a mission to lower the carbon emissions of their vehicles. But simply swapping out internal-combustion engines (ICEs) is not enough. The entire vehicle lifecycle must be considered. This includes the design, material sourcing, manufacturing, recycling, and time on the road. Autovista24 journalist Rebeka Shaid, editor Phil Curry, and deputy editor Tom Geggus discuss the green efforts of car companies.

You can listen and subscribe to receive podcasts direct to your mobile device, or browse through previous episodes, on Apple, Spotify, Google Podcasts and search for Autovista24 Podcast on Amazon Music.

Show notes

How can electric-vehicle batteries become more sustainable?

McKinsey: The zero-carbon car: Abating material emissions is next on the agenda

WEF: The Circular Cars Initiative

VW Group: ŠKODA AUTO uses eco-materials in its vehicles and is researching biological raw materials

Hyundai cleans up cars and the ocean in sustainability drive

Continental: Sustainable materials in cars of the future

Volvo: Volvo Cars to go leather-free in all pure electric cars as part of animal welfare ambitions

Porsche: Digital, clear, sustainable: the interior of the new Porsche Taycan

IEA: Iron and steel technology roadmap

VW inks green steel deal for automotive manufacturing as it focuses on sustainable supply chains

Polestar seeks sustainable automotive supply-chain partners for carbon-neutral car

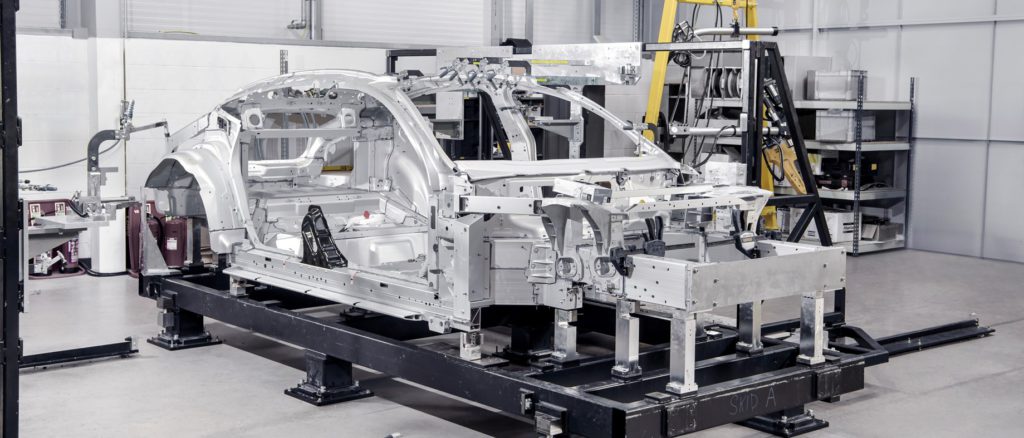

BMW considers lifecycle of a vehicle with fully-recyclable car

Podcast synopsis

Carmakers are on their way to carbon-neutrality, focussing on electrification to achieve ambitious climate-target goals. But electric vehicles (EVs) alone will not decarbonise transportation, which is why the automotive industry is increasingly integrating sustainability into manufacturing.

Green concept cars have been drawn up as a blueprint for future design ambitions. The Polestar 0 project and BMW i Vision Circular will push both carmakers into new territory. They will require enormous amounts of planning, effort, and investment to achieve greener car lifecycles. But the companies will not be able to act in isolation and will need full commitment from their suppliers and supply chains to ensure sustainability.

McKinsey, the consulting firm, estimates that 60% of automotive industry emissions by 2040 will come from materials used in production, making the need for eco-friendlier materials apparent. Leather made from cactus or pineapple fibres, floormats produced from recycled fishing nets, sugar-beet fibres used as plastic fillers, and green steel, are just a few examples of how the automotive industry is reinventing itself on the road to carbon-neutrality.

The Circular Cars Initiative, a group of businesses set up by the World Economic Forum, makes it clear that carmakers and automotive suppliers must tackle emissions embedded in vehicle materials, in tandem with electrification. The goal is to cut emissions in the supply chain and increase the use of sustainable and recycled materials in car production which plays a major role in making the automotive industry cleaner.

However, a car’s carbon emissions are greater than the sum of its parts, particularly if the energy used to build it comes from non-sustainable sources. Renault, Audi, Volkswagen (VW), and BMW are all making efforts to power their plants with cleaner energy. This includes the use of solar, wind, and battery farms. On top of this, car companies will also have to ensure the electric vehicles they produce can be recharged with clean energy, rather than electricity generated by burning fossil fuels.