German new-car market in ‘reverse gear’

04 August 2022

The German automotive industry is still recovering from a shortage of primary products and surging raw material prices, which are limiting production. The sector is far from being back to normal, with the number of new cars registered each month serving as an indicator of how the market is recovering.

The latest figures from German’s automotive industry association, the Kraftfahrt-Bundesamt (KBA), show that new-car registrations totalled 205,911 units. This represents a double-digit decline of 12.9% year on year, which follows the previous month’s sharp decline of 18%. In the first seven months of 2022, around 1.44 million new cars were registered, a year-on-year fall of 11%.

‘The second half of the year has started disappointingly. The German passenger car market remains in reverse gear,’ said Reinhard Zirpel, president of the Association of International Motor Vehicle Manufacturers (VDIK).

‘In the first seven months, even fewer new cars were registered than in the same period of the coronavirus year 2020. However, it remains the case that the market does not reflect the true demand situation due to ongoing delivery problems. Order backlogs remain very high. Customers want to buy more cars than are available.’

While Germany performed below expectations in July, adjusted for working days, the year-on-year downturn improved to -8.7% from -14.2% in June. The seasonally-adjusted annualised rate (SAAR) also improved from 2.46 million units in June to 2.51 million in July.

Autovista24 has revised its Germany forecast and predicts that the new-car market will be down 0.6% this year to a total of 2.61 million registrations. This sluggish development has been reflected across other European automotive markets because of mitigating circumstances, such as July’s heatwave.

Cutting EV incentives

A wider look at the German new-car market shows that battery-electric vehicles (BEVs) are on the rise, making up 14% of new-car registrations last month. The number of fully-electric cars grew by 13% year on year in July, while the combined volume of hybrid-electric vehicles (HEVs) and plug-in hybrids (PHEVs) fell 14%. Nevertheless, hybrids still accounted for nearly 30% of newly registered cars last month.

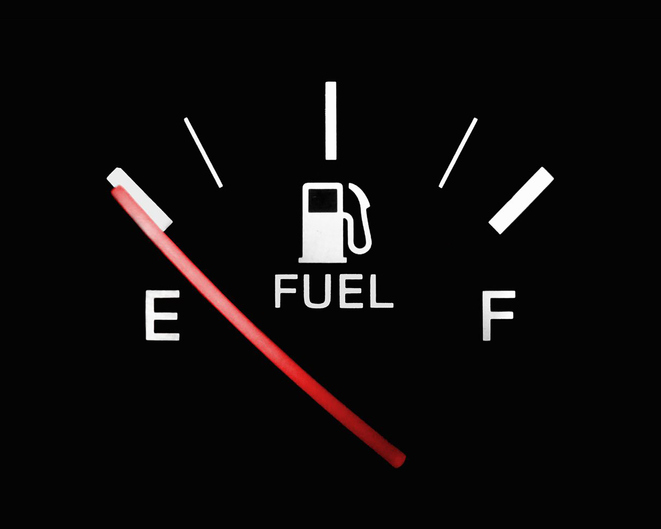

With the number of electric vehicles (EVs) growing, the German government is now aiming to cut incentives. Under current plans, PHEVs will no longer be subsidised from January 2023.

Incentives for BEVs costing under €40,000 will drop to €4,500 next year from €6,000, and cars priced over €40,000 will be subsidised with €3,000, compared to the €5,000 currently available.

From 2024, incentives will drop again, with higher-priced BEVs no longer being incentivised. In the near future, company cars will also no longer benefit from subsidies as these will only be available to private customers from September 2023.

‘Given that demand for BEVs currently outstrips supply, which results in long delivery times with many carmakers, the incentives have started to lose their initial purpose,’ said Sonja Nehls, Autovista24’s principal analyst.

‘BEVs have been less affected by list-price increases so far. While internal-combustion engine (ICE) vehicles in Germany have seen an average price increase of 7% since March 2019, BEVs have only increased by 2%, PHEVs by almost 4%. The net effect of reduced government incentives therefore does not compromise the attractiveness of EVs compared to their ICE counterparts,’ she added.

But Nehls cautioned that dropping subsidies for PHEVs could impact private customers who are not yet ready to switch to all-electric cars as PHEVs ‘can be seen as a steppingstone towards full electrification and – when charged and driven appropriately – have lower emissions compared to a regular ICE vehicle.’

The VDA has condemned cutting incentives, saying it was the wrong time to do so as costs are rising for consumers. It argued that lowering subsidies would slow down the transformation to electromobility.

VDA president Hildegard Müller criticised that incentives would only be paid out to private car buyers from 1 September 2023, which would then exclude company cars. ‘A switch to electromobility is needed in all fleets. It is precisely the company cars and other cars used commercially that then come to the used-car market at lower prices and thus ensure a more climate-friendly fleet overall,’ she said.

The new agreement has another catch as the overall funding for BEVs will be limited to €2.1 billion in 2023, and €1.3 billion in 2024. Once this money has been allocated, drivers will no longer be able to apply for incentives. But tax advantages for electric company cars will reportedly not be abolished.

Protecting supply chains

Meanwhile, passenger-car production in Germany rose for a third month in a row. In July, German manufacturers produced 263,400 cars, up 7% from a year ago. Since the start of the year, 1.9 million passenger cars have rolled off the production lines in the country, a 2% decline when compared to the same period in 2021. ‘The production level from the pre-coronavirus year 2019 is still a long way off and has been undercut by 32% in the current year,’ the VDA said.

While carmakers have adjusted to supply-chain shortages, disruptions are still hampering production. Almost 90% of surveyed automotive companies reported a lack of intermediate products in manufacturing. Mercedes-Benz is grappling with a shortage of certain semiconductor components, with the luxury manufacturer pausing production at one of its German sites in Rastatt due to ongoing supply bottlenecks.

The luxury brand is trying to safeguard supply chains. With the war in Ukraine threatening gas supply in Germany, Mercedes-Benz said it would cut or substitute the use of natural gas in vehicle production. ‘Mercedes-Benz sees a gas reduction potential of around 50% in Germany without impact if regional pooling is possible. The company’s long-term goal is to switch from gas to electricity and other renewable energy sources,’ it said.

Volkswagen echoed similar sentiments in its recently published H1 report. The manufacturer spoke of uncertainties regarding energy supply. But it highlighted that supply constraints have eased, especially the sourcing of wiring harnesses, which is almost back to normal.

Premium brand BMW said it experienced lower sales in the first half of the year because of supply bottlenecks for semiconductors and other specific parts, which impacted production and deliveries.

All of this comes against the backdrop of high inflation, although it dropped slightly for the second month in a row to an estimated 7.5%.